Game, set, print

-

- from Shaastra :: vol 04 issue 08 :: Sep 2025

How to mend bones, prevent injury, and make green cement.

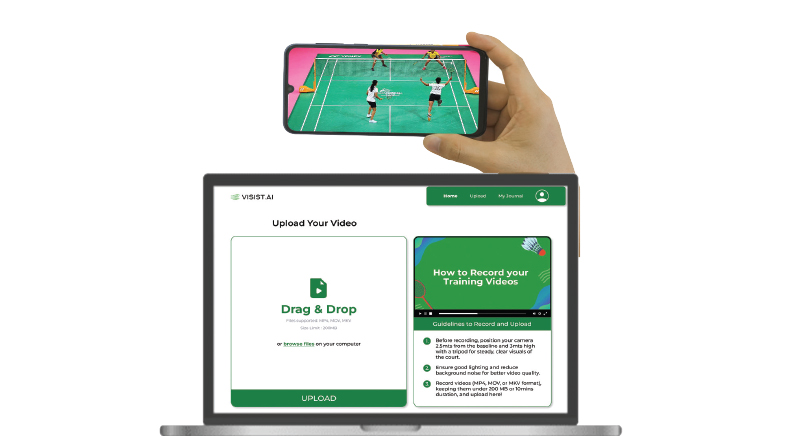

VISIST.AI TECHNOLOGIES

Founders: Suresh Chintada and Seshadri Raghavan

Year: 2024

Big idea: To use video-based AI for training and coaching in sports

Suresh Chintada runs marathons, and Seshadri Raghavan plays tennis. It troubled the two sports lovers, who had worked together at a multinational company, that science and technology did not figure in games played by the average Indian. Only the elite, it seemed, used science to hone their athletic skills. "This was a topic of conversation for us," says Seshadri, who graduated in Physics from Madurai and completed his ME in Computer Science from the Indian Institute of Science (IISc), Bengaluru.

To integrate science into running, they developed an application in 2019 that incorporated sensors and wearables to inform users whether it was a good day for a run and how hard they should train based on the prediction. "We test-drove the app but did not launch it," Suresh says.

They were back at their corporate jobs, but would meet often as their sons played basketball. Suresh says his son was prone to ankle sprains, and they wanted to understand whether there was any way to avoid an injury, and if they could build a solution for that. This was the premise on which they launched Visist.AI, which uses video-based artificial intelligence (AI) and machine learning for sports training. Their goal is to utilise AI to prevent athletes from injuring themselves. "Using the posture, movement and how you play, if you continue to jump in a certain fashion or land in a certain way, I should be able to tell you whether you will be injury prone," Suresh says.

They started with badminton, working with coaches and academies in Bengaluru. Seshadri says they have a large corpus of data on various strokes in badminton and how players move on the court. They biomechanically highlighted the key points and limb movements, which were annotated with the help of reputed coaches. This input gave them an idea of the correct postures and strokes, as well as the right way to jump, bend, or move on the court.

The company's two offerings — Smart Assessment and Smart Journal — are designed for different purposes. The former is for coaching academies; the latter is for individual users. Smart Journal enables users to get feedback on their game. The company will shortly launch the Smart Assessment product in Bengaluru. Incubated at the Foundation for Science Innovation and Development at the IISc, Visist.AI plans to offer these services for other sports after it launches the badminton products. The facility will shortly be available on an app. Suresh and Seshadri believe that there is a global market for their product.

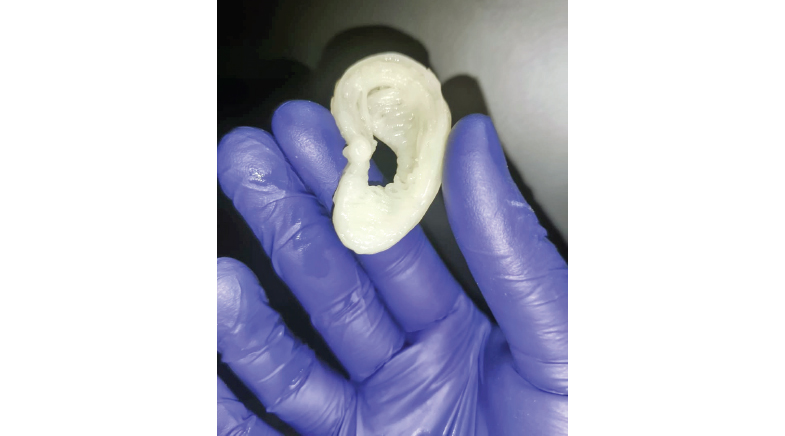

MEDRINZ BIO

Founders: Kaushik Chatterjee, Indranil Chakraborty and Chandan Chatarjee

Year: 2024

Big idea: To develop 3D-printed orthopaedic implants

Kaushik Chatterjee of the Indian Institute of Science (IISc) worked on tissue reengineering using biodegradable materials during his postdoctoral research at the National Institute of Standards and Technology in the U.S. Indranil Chakraborty, who was a postdoctoral researcher in Chatterjee's IISc laboratory and then joined the private sector, suggested they come together to make orthopaedic implants. Chatterjee, currently the Chair of the Department of Bioengineering at the IISc, had completed his PhD in Bioengineering from Penn State College of Medicine; Chakraborty had earned his doctorate in Inorganic Chemistry from the S.N. Bose National Centre for Basic Sciences in Kolkata.

Chatterjee and Chakraborty established MedrinZ BIO, a start-up incubated at the Foundation for Science Innovation and Development, to develop orthopaedic implants using 3D printing. The researchers came into contact with a clinician at a government hospital in Bengaluru who was seeking an engineering partner to develop 3D-printed bone implants for corrective surgeries. Chatterjee's research group collaborated with the doctor and customised implants for his patients. These implants have been used for more than a dozen patients, Chatterjee says. "We have one year of follow-up data, and we recently published a paper," he adds.

The company is developing implants with bone scaffolds to repair irregular defects and 3D-printed polymer scaffolds to self-fit into irregular and complex tissue defects to promote bone growth as well as resorbable orthopaedic implants. To begin with, they focused on conventional materials used in orthopaedic applications but innovated the manufacturing technique. "As a materials lab, we are trying to find the right balance between something that is not too high a risk for the patient and one that offers significant benefits over conventional technology," says Chatterjee.

It plans to use soft polymers and soft gels for regeneration purposes. The team is working on advanced fracture fixation and bone reconstruction using absorbable alloys that degrade safely within the body after the bone has regenerated.

Chakraborty says the company has partnered with a manufacturing company to produce the implants. The first product, utilising titanium, is expected to be released by the end of 2025, and products featuring soft polymers and gels are slated for launch in approximately two years. The orthopaedic implants market is substantial and growing at a steady pace annually — the market in 2023 was estimated at ₹55,000 crore and growing at 8% CAGR.

NOVACRET (ECOSTRATA INFRA)

Founders: Vijay Yashwanth, K.S. Nanjunda Rao and Nithin N.

Year: 2024

Big idea: To produce green cement using industrial waste

The construction industry spews toxic fumes — accounting for 11-13% of global greenhouse gas (GHG) emissions. The cement industry contributes 8% of that, points out K.S. Nanjunda Rao, Chief Research Scientist, Department of Civil Engineering, Indian Institute of Science (IISc). The industries have been trying to reduce GHG emissions. The cement sector, for instance, has been mixing fly ash from thermal power plants and slag, a by-product of the steel industry, into Ordinary Portland Cement (OPC) or grey cement to reduce emissions.

PHOTO: N. RAMAKRISHNAN

PHOTO: BY SPECIAL ARRANGEMENT

(From left) K.S. Nanjunda Rao, Vijay Yashwanth and Nithin N. of Novacret

But what if green cement could be produced using the waste by-product of steel plants and thermal power stations and used as a binder in non-structural applications? The idea led Rao to set up Novacret (Ecostrata Infra) with Vijay Yashwanth and Nithin N.

Rao's work at the IISc focused on utilising industrial waste for green cement. He was pleasantly surprised when two civil engineering graduates — Nithin, from the University of Kerala, and Neil Kevin Martis, who graduated from the National Institute of Technology Surathkal, where Rao was an adjunct faculty member — showed an interest in starting a venture to utilise industrial waste for cement production. Martis, an adviser to Novacret, had previously worked in another venture with Yashwanth, an Electronics and Communications Engineer.

Novacret utilises Ground Granulated Blast Furnace Slag (GGBS), a by-product of steel plants, and fly ash from thermal power plants as raw materials for its green cement. Rao and Yashwanth say they use a proprietary technology that involves mixing alkali activators with the GGBS and fly ash. Rao points out that initially, fly ash and GGBS were only used as partial replacements for Portland cement in concrete; however, their efficacy has now been proven as a replacement in non-structural applications. There are several benefits to using geopolymer-based materials. They achieve full strength in only three days, as against the 28 days needed for OPC. The materials require less water, and their CO2 emissions are negligible compared to OPC, he adds.

Novacret has tied up with manufacturing partners to produce concrete paver blocks with green cement. These blocks have been used in a few buildings. "The cement we make can be used for engineering blocks, landscape and precast products such as paver blocks, kerb stones and drain covers. We are also doing R&D on engineering blocks like AAC (Autoclaved Aerated Concrete) blocks. They are stronger than regular concrete blocks," says Yashwanth.

Novacret, he says, will offer the green cement in bags, like traditional cement companies. The start-up, however, is still working out the costs. "We want to commercialise green cement. Our strategy is to target the precast blocks market first and then the engineering blocks. We will target only the manufacturers of these products," Yashwant says.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH