Now, a cheaper way to convert CO2 to methane

-

- from Shaastra :: vol 01 edition 03 :: Sep - Oct 2021

Preventing carbon dioxide (CO2) from escaping into the atmosphere by capturing it is an effective way of fighting climate change (see 'Cleaning up their act'). This works well in thermal power stations, where large amounts of CO2 are produced. But carbon capture is still not cost-effective for widespread commercial use. Scientists have been trying to reduce the cost of carbon capture. It is estimated that the per tonne cost of carbon capture has to come down by half - to $30 per metric tonne - to be cost-effective.

Coal-fired power plants use diverse carbon capture methods. They range from water-rich solvents that douse exhaust gas, or flue gas, before it is emitted from plant chimneys to more energy-efficient membranes that filter CO2 out.

A U.S. research team, which included India-born chemist Jotheeswari Kothandaraman (pictured below), recently found that a solvent it developed at the Pacific Northwest National Laboratory (PNNL) of the U.S. Department of Energy could more efficiently convert such captured CO2 into methane, the primary component of natural gas. Kothandaraman, a chemist at PNNL, studied in Chennai's Stella Maris College before moving to the U.S. for her doctoral and post-doctoral studies.

The CO2 capture cost using traditional technologies is $58.3 a tonne; the new method can lower it to $47.1 a tonne.

The PNNL solvent EEMPA (N-[2-ethoxyethyl]-3-morpholinopropan-1-amine) can lower CO2 capture cost to around $47.1 per tonne - from $58.3 a tonne using traditional technologies.

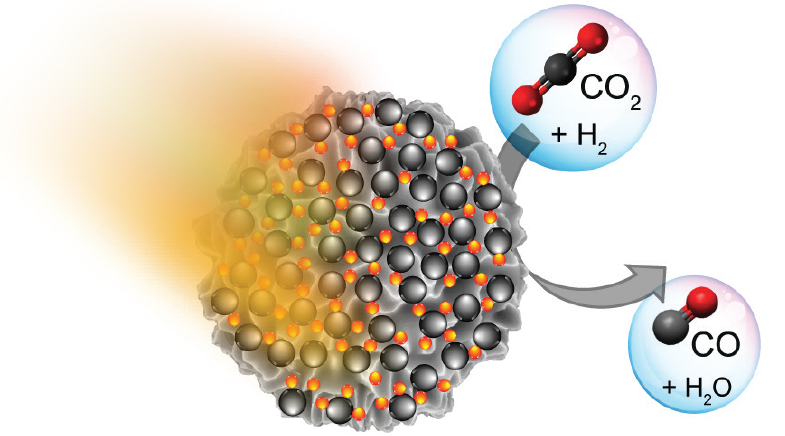

The production of methane became possible because EEMPA overcame a serious shortcoming that conventional solvents suffered from. In a traditional solvent, the relatively high water content made methane conversion difficult.

The work by the scientists appeared in August in ChemSusChem journal, published by Chemistry Europe, an association of 16 chemical societies from 15 European countries.

What is significant about the work is that it not only captures CO2 but also finds ways to effectively use it. EEMPA reduces the material needed to run the reaction and the energy required to power it, which lowers the price of the methane produced.

When compared to the conventional method of methane conversion, the new process requires an initial investment that is 32% lower. Operation and maintenance costs are 35% cheaper, bringing the selling price of synthetic natural gas down by 12%, the team claimed.

Even though different methods to convert CO2 into methane have been known for long, most of these processes rely on high temperatures and, as a result, are too expensive for widespread commercial use.

In addition to geologic production, methane can be generated from renewable or recycled CO2 sources and can be used as fuel or as a hydrogen energy carrier. Though it is a greenhouse gas and requires careful supply chain management, methane has many applications, ranging from household use to industrial processes, Kothandaraman, lead author of the paper, said.

"Right now, a large fraction of the natural gas used in the U.S. has to be pumped out of the ground, and demand is expected to increase over time, even under climate change mitigation pathways," she said. "The methane produced by this process - using waste CO2 and renewably sourced hydrogen - could offer an alternative for utilities and consumers looking for natural gas with a renewable component and a lower carbon footprint."

Besides, the process offers additional cost savings. According to the scientists, CO2 captured by EEMPA can be converted to methane on site. Traditionally, CO2 is stripped from water-rich solvents and sent offsite to be converted or stored underground. Under the new method, captured CO2 can be mixed with renewable hydrogen and a catalyst in a simple chamber, then heated to half the pressure used in conventional methods to produce methane.

The reaction is efficient, converting over 90% of captured CO2 to methane, the authors said. The ultimate greenhouse gas footprint depends on what the methane is used for. And EEMPA is capable of capturing over 95% of CO2 emitted in flue gas. The new process gives off excess heat, too, providing steam for power generation.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH