Best out of waste

-

- from Shaastra :: vol 04 issue 09 :: Oct 2025

Researchers are disposing of industrial waste in innovative ways.

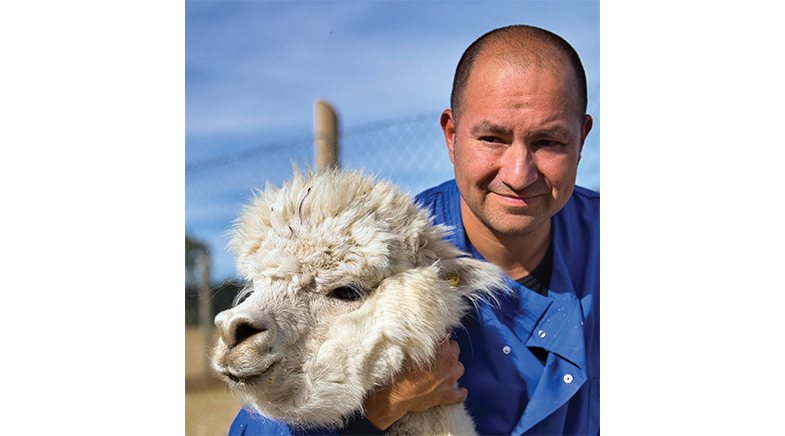

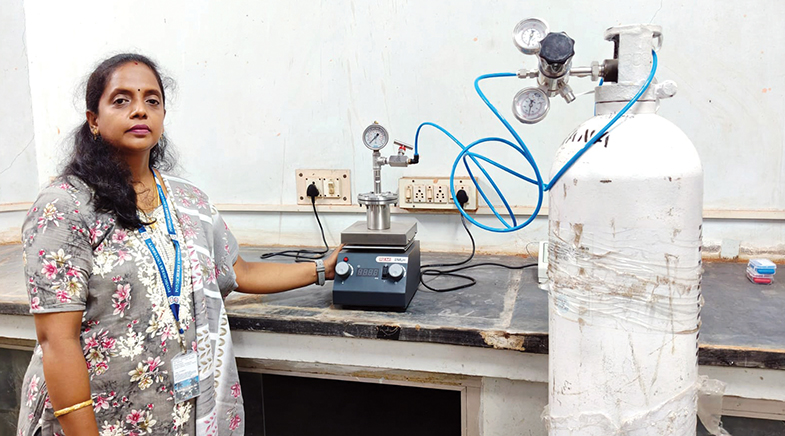

T.D. Rushendra Revathy has a one-shot solution to the two vexing issues of carbon footprints and industrial waste. At her laboratory in Pondicherry University, she has been increasing the carbon capture capability of steel slag, a by-product of the steel manufacturing process. This, she believes, can address the problems of waste and pollution posed by the steel industry.

Revathy began work on this during her PhD, when she tested various industrial wastes — such as steel slag, fly ash from the coal industry and red mud from the aluminium industry — to capture carbon. Carbon dioxide is an acidic gas, and as these wastes were all alkaline, they could capture carbon. "Steel slag has a very good alkaline content of above 50%. So why don't we capture carbon dioxide using that alkaline content?" she asks.

Scientists are not only working on using waste but also ensuring that it is fully utilised, leaving nothing to be treated or buried.

Steel slag has oxides of calcium, silicon, aluminium, iron and magnesium. Carbon dioxide reacts with calcium oxide to form calcium carbonate, a solid form. To enhance this reaction, Revathy, an Assistant Professor at the university, tested three factors — reaction type, pressure, and temperature — for her PhD, carrying out both wet and dry reactions. She used a continuous reactor for the wet reaction: steel slag was mixed with water, and carbon dioxide bubbled through. In another type of reactor, the fluidised bed reactor, carbon dioxide gas was blown through dry steel slag powder, allowing the reaction to occur in a dry condition. The wet reaction sequestered carbon dioxide more efficiently than the dry reaction process and at a lower temperature. The study found that a water-to-slurry ratio of 14.5:1, a temperature of 61° Celsius and a pressure of 46.24 bar could sequester 127.4 grams of carbon dioxide per kilogram of slag. India produces 36 metric tonnes of steel slag every year, and this reaction, she explains, will enable the sequestration of 3 metric tonnes of carbon dioxide (bit.ly/slag-carboncapture).

Revathy is now extending the PhD work in her lab at the Centre for Pollution Control and Environmental Engineering at Pondicherry University. Her team has found that the sequestration capability of steel slag can be further enhanced to 300 g per kilogram of steel slag by decreasing the particle size of slag through grinding. The team is also testing whether treating slag with chemicals increases its sequestration efficiency. Although steel slag can be directly used as a partial replacement for cement, slag with captured carbon is stronger, making it a better construction material. Further, the procedure prevents slag from filling landfills and carbon dioxide from polluting the air. Revathy points out that the steel industry itself produces carbon dioxide; a carbon capture plant can make its operation environmentally friendly.

VALUE FROM WASTE

After Independence, Indian industries expanded rapidly, helping the country grow. However, the use of high resources and the lack of pollution and waste control have left a deep impact on the environment. The pollutants include — apart from fly ash, steel slag and red mud — cement kiln dust from cement, and hazardous chemical waste from pharmaceutical, chemical, and petrochemical industries. Thermal industries alone produce 340 million tonnes of fly ash annually, and a tonne of steel produces 150-200 kg of steel slag. Non-toxic waste, such as steel slag, fly ash, and red mud, has for long been disposed of in landfills, but there is not enough space for such waste dumping.

However, with the global movement for sustainability gaining momentum, regulations have been introduced to curb pollution. With export markets also showing an interest in working only with industries that adhere to green practices, it is becoming imperative for Indian sectors to adopt sustainable and circular practices. Industries are now collaborating with scientists and start-ups to utilise waste in a bid to follow circularity guidelines.

Institutes are stepping up. The Council of Scientific & Industrial Research (CSIR)-Central Road Research Institute has developed an "Eco-fix" process for pothole repair by combining steel slag with tar. Slag is also being used to partly replace cement used for highways. Fly ash is being utilised to make bricks: the National Thermal Power Corporation has built a house using such bricks in Chhattisgarh's Bilaspur district. As fly ash is rich in nutrients, alkaline in nature and has good water-holding properties, it is being explored for use in agriculture. The Jharkhand-based CSIR-Central Institute of Mining and Fuel Research has developed a fly ash-based soil conditioner-cum-fertiliser by combining 80-90% of fly ash with other nutrients. Similarly, red mud has also been shown to be effective for soil stabilisation and wastewater treatment (bit.ly/Shaastra-Red-Mud). A study by researchers in the U.K. has also shown that red mud-molten salt composites are effective for medium- to high-temperature thermal energy storage (bit.ly/redmud-thermalstorage).

HOLISTIC UTILISATION

Like Revathy, Inkollu Sreedhar, Professor at the Hyderabad-based campus of the Birla Institute of Technology & Science Pilani, has been successfully capturing carbon. After developing a zeolite catalyst for carbon capture from fly ash, he explored other applications of fly ash based on its properties. With his expertise in wastewater treatment, he knew that removing heavy metals from wastewater required a high surface area, for the heavy metals to sit and interact, and a chemical affinity towards heavy metals. So, he combined chitosan with fly ash. Chitosan, a biodegradable polymer derived from fish scales, has negatively charged groups that attract positively charged heavy metals. Fly ash provides a large surface area where heavy metals can adsorb and interact with chitosan. This combined absorbent was able to remove 352.19 milligrams of lead ions per gram of absorbent and 265.13 milligrams of chromium ions per gram of the absorbent. The absorbent could be regenerated after eliminating heavy metals and reused for up to 15 cycles (bit.ly/flyash-wastewater). He says the heavy metal-laden absorbent can even be used in supercapacitor applications. Sreedhar now plans to collaborate with electrical engineers to follow up on this line of research.

Revathy's team has found that the sequestration capability of steel slag can be enhanced by decreasing the particle size of slag through grinding.

Scientists are not only working on using waste but also ensuring that it is fully utilised, leaving nothing to be treated or buried. They offer a waste value chain solution to industries. Scientists Pratima Meshram and Abhilash (he uses only one name) from the Jamshedpur-based CSIR-National Metallurgical Laboratory have developed a process that ensures the total utilisation of red mud. In this process, they first recover leftover aluminium from red mud, followed by iron recovery through smelting. Titanium and rare-earth elements are then extracted from the leftover slag. Finally, the residue, which contains calcium silicate and gypsum, is geopolymerised to produce paving blocks and other materials used in the construction industry. Apart from disposing of waste, the process enables the production of iron and aluminium at a cheaper rate, as it does not require mining. It consumes only a fifth of the energy that most normal processes do, and yields rare-earth metals, which are at present mostly imported. While the concentration of rare-earth elements is low per kilogram, the potential is enormous. India, which already has nearly 23 million tonnes of red mud, generates 5 million tonnes of it annually.

While countries such as Greece already have this technology, Abhilash says that it is necessary to have indigenous solutions rather than importing them, as the composition of Indian waste differs from that elsewhere. "Greek ore contains 7-8% iron," he says. Indian ore contains a minimum of 32% iron. "So we had to tweak the Greek process of the science available and make it useful for Indian material," Abhilash explains.

Science and industry are collaborating for lasting solutions. If they can have their way, nothing will go to waste.

See also:

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH