Flush with treasures

-

- from Shaastra :: vol 03 issue 05 :: Jun 2024

Technological fixes to broken sewage treatment systems are ensuring that waste and money don't go straight down the drain.

For over a month earlier in 2024, the Transport Nagar area in Lucknow was reeling from a civic emergency with serious public health consequences. Water from the taps was emitting a stench, which hinted at water contamination, but the source could not be traced. This wasn't the first time Uttar Pradesh's capital city was facing such an eventuality: recent years have seen a spate of such instances of sewage getting mixed up with potable water. Indeed, people in many cities across India have had similar experiences.

Since 2021, SUEZ, the company contracted to manage the sewage network and wastewater treatment plants in various Indian cities, has been partnering with Solinas Integrity, a Chennai-based start-up that has carved a business out of addressing problems relating to water contamination, leakages and blockages. Broadly, the challenge lay in identifying the precise points where contamination happens along the miles of separate, underground pipes that carry life-sustaining water and excremental sewage. Sewage is corrosive, and in the event of a leak, it can seep into the pipes bearing water. And as Moinak Banerjee, Co-founder of Solinas Integrity, observes, there isn't even a grid map of the pipelines, laid decades ago.

Gone with the flush, our waste travels a long distance through a network of pipes before it is finally treated in sewage treatment plants.

Remediation in such situations typically centred around digging holes at random to locate the leaky spots. But Solinas has a technological fix. It comes in the shape and form of Endobot, a tiny robot devised (and patented) by the company; the robot moves and scans through the pipes and sends out information on the geolocation of leaks and overflows. Solinas's software dashboard Swasth AI captures the information (see 'No taste for waste').

Similar robots have been used in the West, but Indian sewer pipes are narrower. In India, major pipelines have a diameter of 100-150 mm, whereas in other countries they are 300-400 mm wide, says Banerjee. The challenge was to create a smaller robot with all the required sensors: the team integrated a laser sensor to measure pipe diameter to find blockages; a camera with sonar to visualise the pipe despite the water being black; an electronic gyroscope that measures the tilt of the pipe – necessary for the movement of sewage water without power; a system to geolocate where the robot is present or has seen a problem; and a gas sensor that warns about the build-up of noxious gases like methane or hydrogen sulphide in the pipe.

OUT OF SIGHT...

Conventional flush toilets, which take away our body waste in a single flush, keep our minds off how our waste is disposed of. But our waste travels a long distance through a network of pipes before it is finally treated in sewage treatment plants that recover water from it. While the toilet design has remained the same for more than a century, new technologies are now helping to manage our body waste effectively.

Rather than being seen as a problem that needs disposal, sewage is today considered a source for extracting resources like fertilisers, manures, biogas and biofuel. The rising population has put excessive pressure on centralised systems, and India and some other countries are looking to decentralise sewage treatment, which has given a push for no-waste toilets that treat waste on-site through incineration, chemical treatment, microbes, etc. Though old and broken, the centralised sewer system, however, remains the backbone of sewer management in Indian metros. Technology is being harnessed to monitor and repair it.

ROBOTIC HELP

Solinas Integrity currently provides services in 12 States in India and is trying to integrate mechanisms through which the Endobot can also clean the pipelines and fix leakages. The team has also developed a cost-effective manhole-cleaning robotic machine called HomoSEP Atom that can homogenise the sludge of septic tanks and manholes, and pump it out using a suction mechanism, thereby clearing and cleaning a blocked pipeline.

One of the aims of the company is to use Endobots to digitise the water and sewer network. "It's very important that we are able to digitise this infrastructure. (It) will be mapped and we will have it in the cloud... so that if there is some problem in a specific civil infrastructure, we will know where the problem is," says Banerjee.

Apart from detecting leakages and predicting overflows, geotagging can help to figure out the origin of infectious diseases like COVID-19, typhoid and cholera, cases of substance abuse as well as a rise in non-infectious diseases, such as diabetes, in a particular community. Toilets that can monitor an individual's health are also being developed. For example, San Francisco-based Toi Labs has come up with TrueLoo, a medical toilet for individuals, with advanced sensors that non-invasively monitor urine and stool contents to warn about health.

Sewage is increasingly being considered a resource rather than waste. Apart from giving a wealth of public health data to guide policy, sewage is being processed to recover resources to drive a circular economy.

RESOURCE RECOVERY

Other than getting rid of waste, one of the prime functions of sewage treatment plants is to treat, disinfect and recover water – a valuable resource. Modern toilets use less water for flushing; some designs obviate the need for water altogether. Researchers have gone beyond recovering water and are now using sewage to recover other valuable resources as well. "There are two main resource recovery aspects in terms of a circular economy. One is energy, the other one is nutrients like nitrogen, phosphorus, etc.," says Srikanth Mutnuri, Professor at the Birla Institute of Technology and Science (BITS) Pilani, Goa.

Sewage is increasingly being considered a resource rather than waste.

With a PhD in environmental microbiology from Anna University, Mutnuri joined BITS in 2005 and has been developing wastewater treatment solutions since then. His team has developed a faecal sludge management plant where microbes act upon organic waste and sewer waste to produce biogas, and another technology wherein septage is processed to produce an organic manure, terra preta.

In 2021, Mutnuri and his team demonstrated that their microbial fuel cell technology can both produce electricity, and recover nitrogen and phosphorus (bit.ly/microbial-cell). In this microbial fuel cell, the anode and cathode are made up of a stainless steel mesh and are separated by a membrane that allows positively charged ions to move. At the anode, microbes act upon the organic matter, producing electrons and positively charged ions. While the electrons are harnessed to produce electricity, the positively charged ions move toward the cathode leading to a build-up of pH. The high pH, and addition of magnesium chloride, led to the precipitation of nitrogen and phosphorus as magnesium ammonium phosphate or struvite. The team connected a series of eight microbial fuel cells to a 10L urinal and produced a voltage of around 3V, which can light a diode or small LED bulb, and were able to recover 90% of nitrogen and 46% of phosphorus. The team plans to extend this finding to public urinals installed at events such as college fests to develop a system of resource recovery.

High energy-intensive processes like Haber-Bosch for ammonia production and finite resources of phosphorus emphasise the need to look for processes that can be used to recover these resources; struvite formation through sewage is one such route. Struvite is a slow-releasing fertiliser and it does not pollute the environment. According to a 2018 study by researchers at the Netherlands-based Delft University of Technology, recovering all urban phosphorus discharged as wastewater (including human excreta, household detergents and industrial effluents) can meet 20% of the phosphorus demand in agriculture (bit.ly/phosphorus-recovery).

Mutnuri is not alone. Various other researchers and companies across the globe are trying to create wealth from sewage waste. Sanivation, a Kenya-based start-up, converts human waste to solid biomass fuel. In 2017, scientists from the DEVCOM Army Research Laboratory in the U.S. developed a nano-powder that turns urine into hydrogen instantly, which can power fuel cells and provide clean energy.

Researchers are also looking to produce value-added products from sewage like extracellular polymers, volatile fatty acids and bioplastics. A 2018 study by researchers at the Belgium-based University of Antwerp (bit.ly/value-added-products) predicted that processing the sludge from sewage treatment plants of the then-28 member states of the European Union could generate up to 2.0 megatonnes of esters, 1.4 megatonnes of polyhydroxyalkanoates (PHA) or 2.2 megatonnes of microbial (or single-cell) protein. Esters are organic solvents used in the paint, chemical-processing and personal care industries; PHA can be converted to bio-plastics; and single-cell protein is a dietary protein source for feed, like fishmeal.

As centralised sewer systems are already strained, the government is now encouraging residential colonies exceeding a certain number of dwellings to install and manage sewage treatment plants. This has spurred the interest of the sanitation sector in coming up with innovative solutions that not only treat the waste but also create a resource.

SELF-SUSTAINING TOILETS

Decentralised systems or off-grid toilets are now increasingly being adopted in new dwellings, village areas and public toilets. These toilets can manage, get rid of the waste and function mostly on their own.

Unhygienic and broken public toilets pushed Mayank Midha, an electronics engineer, to start the Faridabad-based GARV Toilets in 2015. Coming from a family of metal manufacturers, Midha decided to develop vandal-proof, prefabricated steel toilets that are long-lasting and recyclable. At a friend's suggestion, he later integrated various smart technologies into it. "We decided to integrate RFID and IoT-enabled sensors onto the toilet to automate the cleaning process and also to report the overall functioning of the toilet," says Midha.

GARV Toilets have auto-flush facility that flushes the bowl after every use and the entire toilet area after five uses. Electricity for lighting and other functions is derived from a solar panel on the roof. Toilets are equipped with motion, occupancy and proximity sensors to keep a count of users and automate the functions. The data from these sensors goes to a dashboard, thus allowing remote monitoring. The toilets use biodigester technology for sewage treatment where the faecal matter is acted upon by microbes to release biogas, compost and water that can be used for gardening. Lately, the toilets have been extended to a sanitation centre that also provides bathing facilities, drinking water, kiosks for dispensing hygiene products, and a laundrette.

Toilets that can get rid of the waste – and function mostly on their own – are being widely adopted.

While Midha's hi-tech toilets are a good model for public toilets, they are unaffordable and impractical for individual households. Since the Swachh Bharat Abhiyan started in 2014 to make India open-defecation-free, there has been a search for low-cost, off-grid technologies that can be implemented in village areas that are not connected to the sewer grid.

GOING OFF-GRID

Marta Vanduzer-Snow moved to India in 2012 and was volunteering for an NGO when she realised that villagers wished to have a toilet in their house, which prompted her to look for a low-cost solution. A permaculture enthusiast, she decided to implement evapotranspiration toilets with know-how sourced from her friend working with the Brazilian government.

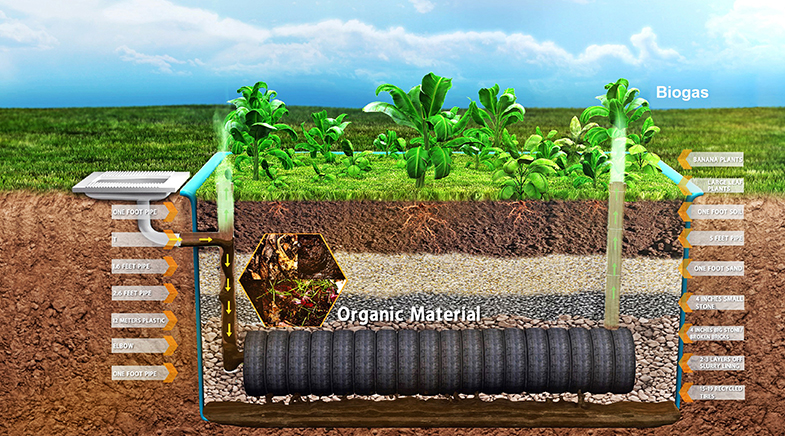

In such a set-up, a trench is dug in the field and a tyre tunnel is created by placing recycled tyres horizontally, and the space around it is filled with broken stones, bricks or porcelain (see graphic). A layer of small stone is poured on top of this structure followed by sand and then soil, over which broad-leaf plants like banana are planted. The faecal waste goes inside this tyre tunnel through a pipe. The liquid waste is absorbed by plant roots; the solid matter turns into minerals and is also eventually utilised by plants to grow. The biogas produced from the anaerobic digestion of organic waste in the tyres is released into the atmosphere from a pipe that is fitted at the end of the tyre tunnel.

All the material can be procured from the local market; the toilet costs ₹14,000 and, if made properly, can function forever. "It's really easy to build, maintain, use. It's inexpensive. It harnesses the power of nature," claims Snow. She registered the Safalgram Development Foundation in 2018 and has been pioneering the development of such toilets in Indian villages through the NGO, which has so far built 500 toilets in seven Indian States.

The hunt is on for other ideas that treat waste on-site. In 2022, the Bill & Melinda Gates Foundation along with Samsung Electronics designed a waterless toilet that uses heat and bioprocessing to kill pathogens to clean the water and turn the solid faecal matter into ashes. A U.S.-based social venture called change:WATER Labs has developed a no-water toilet that uses a membrane to soak up and evaporate liquid content, leaving behind a small amount of dry solids that can be taken out fortnightly or monthly.

Likewise, the world now has enough technologies to keep its shit together!

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH