Macro issues, micro solutions

-

- from Shaastra :: vol 04 issue 04 :: May 2025

Microbes are a low-cost and sustainable answer to water pollutants.

Deepor Beel in Assam is a classic 'before-and-after' story of a wetland in crisis. In December 2022, Punyasloke Bhadury received a phone call from Nature Environment & Wildlife Society, a Kolkata-based non-governmental organisation, seeking a solution to heavy sewage entering the beel (lake in Assamese). It is the State's only designated Ramsar site — a wetland of international importance designated under the Ramsar Convention — and a natural storm water reservoir for Guwahati during the monsoon season. Its ecology was severely affected by the constant sewage inflow, impacting the health and livelihood of not just the wetland, but local communities, too.

A Professor of Biology at the Indian Institute of Science Education and Research (IISER) Kolkata, Bhadury is no stranger to such problems: he has been working on nature-based solutions to ecological restoration for over a decade. In particular, he has developed microbial consortia-based formulations capable of cleaning pollutants from water. After consulting other stakeholders, he visited the lake over the next few months and put his solution in place.

A grid of cylindrical floating units packed with microbes was laid in the Pamohi River — a sewage-laden river that drains into Deepor Beel — by July 2023. The floating units were placed on a 1-km stretch where the river enters the beel. "And in one year, despite the flow of the raw sewage, the water quality improved significantly," Bhadury says.

The foul smell from the area has gone. In the 1-km stretch, the water's Biological Oxygen Demand and Chemical Oxygen Demand values (measured to assess the amount of organic matter in a sample) have improved, and there are no faecal coliform bacteria, he says. Aquatic vegetation is returning, and he hopes that the fish population will be back, too.

Two critical factors underpin the success of this bioremediation strategy: the choice of microbes and the ability of the microbes to function optimally.

Two critical factors underpin the success of this bioremediation strategy: the choice of microbes and the ability of the microbes to function optimally in real-life conditions. For this case, Bhadury used a consortium of nearly 25 bacteria, each selected for its ability to reduce pollution in a specific way and being suitable for the local environment. "All the bacteria that we use are indigenous," Bhadury emphasises. "We are very sensitive to biological invasion issues".

Bhadury points out that there are several scientific publications about microbe-based strategies to clean rivers. But while these work in laboratories, the solutions fall apart when taken for field validations. This is because, he says, the cleaning bacteria cannot stay put in the flowing river. They get detached from the matrix and float away. To address this problem, Bhadury and his collaborators have developed a matrix that can withstand a high water flow rate. The bacteria are attached to the matrix and put inside hollow tubes with small pores. As the water passes through the tube, the bacteria eat up the contaminants, and clean water goes out of the tube and onto the other side.

The water's flow rate is an important factor in the success of these solutions. During the rainy seasons, rivers in the Northeast are in spate. The current is often so strong that any structure in the water will likely come apart. Bhadury says their solution can withstand a flow rate of 3.5 m/sec and flood-like conditions.

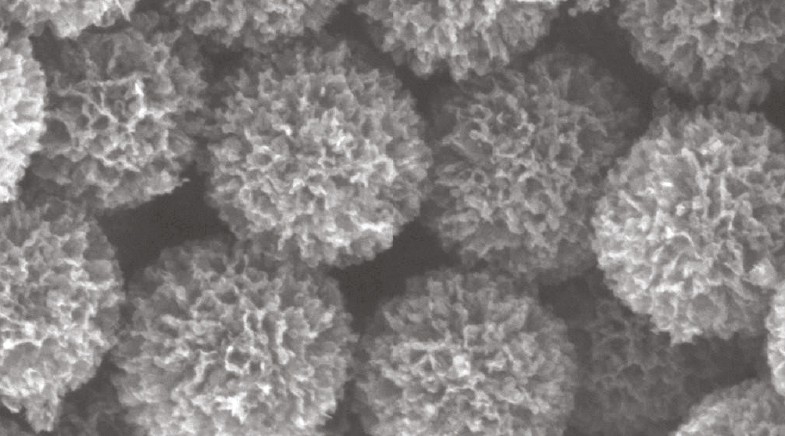

Made from waste biomass, the matrix is a biopolymer shaped into spheres with unique physical, chemical, and biological properties. Currently, the matrix is produced in Gurugram with waste biomass from paddy fields by a pilot-scale start-up. Its design and structure were developed by Bhadury and his long-time friend, Bhoopesh Mishra, Associate Professor of Physics at the Illinois Institute of Technology, U.S. The two first met in 2006 as postdoctoral candidates at Princeton University.

Mishra explains that, on the physical side, a hierarchical porous structure helps trap ions of different sizes. Chemistry-wise, there are catalytic properties that can either completely break down the contaminant or reduce it to a level that it is converted into benign materials, he adds. The researchers have found the matrix can break down troublesome contaminants such as pesticides and microplastics (see 'A bowl of plastic, anyone?', p 45). The biological properties of the microbes are the matrix's third layer of abilities: the structure holds the microbial consortia metabolising the pollutants. "The innovation is integrating the physical, chemical, and biological properties in one go. It is also low-cost, sustainable and scalable," Mishra says. It allows for customisation at two levels: the structure of the matrix and the choice of microbes.

The solution is based on the concept of microbial fuel cells, in which microorganisms convert the chemical energy in organic compounds into electrical energy.

The remedial bacteria are chosen based on a region's ecology. "Our mantra has always been to use the local bacteria for local solutions," Bhadury says. He is, for example, working on cleaning a Kolkata wetland next to a leather complex with a set of microbes that work specifically against the pollutants there. Because of effluents from the leather complex, the site has been polluted with chromium. So, the chosen microbes help remove chromium from water. Bhadury now has a repository of 60 species of microbes that can be used for bioremediation; he wants to set up a national culture collection facility that enables people to use these microbes for academic or industrial processes.

GENERATING POWER

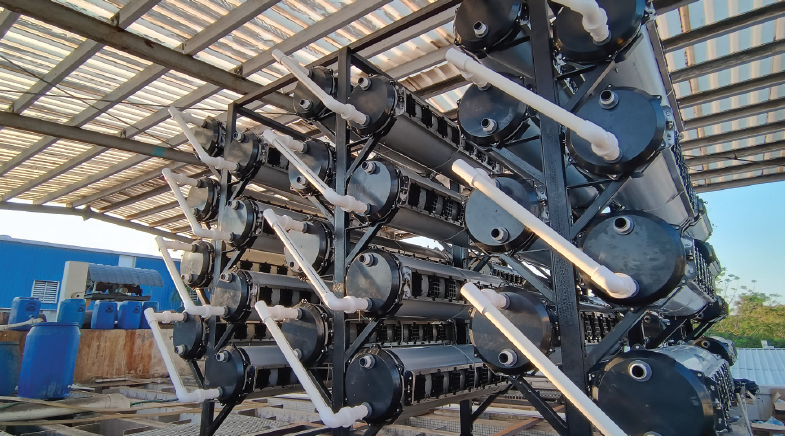

Chennai-based start-up JSP Enviro uses bacteria to clean dye-laden waste from textile factories — and produce electricity in the process. JSP Enviro co-founders Priyadharshini Mani, Suresh Paul Jones and Fidal Kumar have developed a strategy to make bacteria found in industrial wastewater electroactive. The electroactive bacteria eat the organic waste in the water and then produce electricity. "It's like an anaerobic process, just like biogas," explains Mani. But instead of gas, electricity is produced.

The solution is based on the concept of microbial fuel cells (MFC), in which microorganisms convert the chemical energy in organic compounds into electrical energy. Like any other type of battery, the MFC has a cathode and an anode. The microbes are attached to the anode, where they oxidise the chemicals in the wastewater, causing electrons to be released. These electrons then travel to the cathode through a circuit, resulting in the production of electricity. The electricity produced is fed back into the system to run it, making the process energy-positive.

The concept of an MFC is over 100 years old, and reams of studies have been published on it. Mani's PhD, too, was based on MFCs. There are examples of MFCs being used to treat industrial wastewater, but they have not been used to treat waste from a textile factory, Mani notes, adding that they are the first in India to develop a large-scale, MFC-based, industrial wastewater treatment technology. The work started in 2019 after basic research and development. "We started with 200-ml bottles in the lab and gradually scaled it to 50,000 litres," Mani says. A typical installation that handles 50,000 litres of waste occupies roughly 500 square metres of space and consists of several MFCs connected in a series.

The start-up, which is in a pre-revenue stage, has successfully tested the technology at a dyeing unit in Erode, Tamil Nadu, and is currently testing it at a textile factory in SIPCOT-Perundurai. While the scale is not large enough for textile factories as they produce nearly 5 lakh litres of waste per day, one of the advantages of the product is that it can easily be scaled, she says.

NOT JUST BACTERIA

Akanksha Agarwal's association with algae has been a long one. Her Master's thesis focused on using algae to produce value-added products; for her PhD, she worked on using waste material as a substrate to grow and use algae. In 2019, after finishing her PhD, she started AgroMorph Technosolutions, a start-up making value-added algae products. "Algae are microscopic plants," she says. Their growth cycle is about 15 times more efficient than regular plants — "which means algae can treat or take up nutrients 15 times faster than plants". A whole range of algal species can be used for different purposes.

AgroMorph's earliest clients were interested in ingredients they could produce from the right species of algae. For two years, this model worked well, but in 2021, Agarwal knew it was time for a pivot. In the two years of operations, she had seen that whatever ingredient they produced using algae required substantial amounts of water. "We were using fresh water and supplementing conventional salts to grow the algae."

Any water treatment modality that relies on microbes needs to ensure that the wastewater itself is not detrimental to the growth and functioning of microbes.

But the issue of water scarcity kept cropping up. That's when Agarwal thought: why not use wastewater to grow algae? She had already explored this idea in her PhD research. "We had a lot of data and research at the back end, and we realised that we could definitely push it forward, at least with domestic wastewater," she says. Domestic wastewater all around the world has more or less the same constitution. Therefore, it's a relatively steady stream to work with."

AgroMorph has successfully grown algae in domestic wastewater at many places and, in the process, produced water fit for gardening and flushing purposes. "We're at a commercial scale in terms of domestic wastewater," Agarwal says. The company is also looking at using algae for denitrification of industrial wastewater. "We are at least two times more efficient than ammonia, the current industry standard for denitrification of effluent," she adds.

TINY BITS

Debnath Ghosal, Associate Professor at The University of Melbourne, wants to use yet another type of microorganism: a nanobacterium. "It is like a really tiny, tiny bacterium. Bacteria are already small, but a nanobacterium is 1/5th the size of a regular bacterium like E. coli," he says.

Ghosal was looking for solutions to the problem of foaming in polluted water. Foaming is a common occurrence in wastewater plants and rivers. Although it can happen for various reasons, such as chemicals and industrial effluents, it often persists in a water system because of a bacterium. "Once the foam forms, it is stabilised by a bacterium called Gordonia amarae," says Ghosal.

To solve this problem, Ghosal and his colleagues were trying to find bacteriophages (viruses that infect bacteria) that could kill Gordonia amarae. But instead of a bacteriophage, they ended up with a nanobacterium: Candidatus Mycosynbacter amalyticus. Lab studies showed that the nanobacterium could readily attach to the foam-stabilising bacteria and kill them rapidly. The researchers published their findings (go.nature.com/3RM3jeD) in Nature Communications in March 2025.

MICROBES AS SENTINELS

Mumbai-based UrbanBlue Technologies also works at the intersection of wastewater and microbes, but its approach is different. Instead of using microbes to remove pollutants, the company uses them to monitor the quality and constituents of the incoming wastewater. It does this by capturing high-resolution images of the microbes in the wastewater and combining these with artificial intelligence for real-time feedback on water quality.

Any water treatment modality that relies on microbes also needs to ensure that the wastewater itself is not detrimental to the growth and functioning of the microbes. Currently, most wastewater treatment plants use sensors to measure the level of oxygen, nitrogen, and so on. "These sensors behave in a reactive way," says Akash Singh, Founder of UrbanBlue Technologies. "They would tell you what is the current status but they wouldn't tell you why that is happening." Using microbes to assess the health of a wastewater plant provides a more incisive picture. Coupled with the actionable insights that the recommendation engine provides in real time improves the efficiency of the wastewater plant significantly.

Singh says the technology will help industrial wastewater plants save 30-60% of operational costs. The start-up is looking to build as many case studies as possible to understand the different ways of reducing costs and making the technology attractive for various industries.

Singh, however, is confident in microbes' ability to stand as indicators. They act as a "canary in a mine", he says, alerting plant operators to any changes in incoming water composition well in time.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH