A clear vision

-

- from Shaastra :: vol 04 issue 07 :: Aug 2025

Looking at farms, products, and energy.

AGRIHAWK TECHNOLOGIES (FYLLO)

Founders: Sudhanshu Rai and Sumit Sheoran

Year: 2019

Big idea: Developing an IoT device for precision farming

Computer science graduates Sudhanshu Rai and Sumit Sheoran were eager to establish a company that would make farming more profitable. They came from agricultural families — Rai was from Uttar Pradesh and Sheoran from Haryana — and had witnessed the many problems that farmers faced. While searching for viable solutions, they analysed nearly 8 million data units from the Kisan Call Centre, a platform that addresses farmer queries.

Rai, who graduated from the Dr. A.P.J. Abdul Kalam Technical University, Lucknow, and Sheoran, an alumnus of the Indian Institute of Technology Roorkee, found that almost 95% of the queries to the centre were about weather patterns, pest attacks, disease incidence, and fertiliser usage. They also observed that farmers engaged in horticulture asked more questions than those working on crops such as paddy and wheat – perhaps because horticulture required decisions to be made on a day-to-day basis. So, the two decided to focus on fruit and vegetable farmers.

They developed an initial version of an IoT (Internet of Things) device with sensors to collect real-time data on farm conditions, enabling them to provide advice to farmers. They started with five grape farmers in Nashik, but realised that the farmers, though enthused by the idea, did not follow it up because they did not think that two people in faraway Bengaluru would know more about their farm than they did. So, the two moved to Nashik to start work with local farmers. The move produced immediate results, with about ten farmers buying the IoT device and following their advice. Now, Fyllo — Greek for leaf — works with about 12,000 farmers in 11 States, with 18,000 installations. The bulk of the business is from Maharashtra, Gujarat, Karnataka, and Madhya Pradesh. They sell aboutt 3,000 devices a month. The farmers buy the IoT device (priced ₹5,999 and above) and pay an annual subscription fee (of about ₹2,000 a year) for the software.

The start-up has developed an upgraded version of the IoT device, named Nero Infinity – Nero is the Greek word for water. It measures soil and weather parameters and advises farmers on issues such as soil moisture status, when to irrigate, and fertiliser use on a mobile app in local languages. Fyllo's 150-strong team includes agronomists, crop physiologists, data collectors and analysts, software professionals, hardware engineers, and sales and marketing personnel. They regularly collect ground data to train their models.

The two-and-a-half-foot-long Nero Infinity device has to be buried in the ground for soil data. Each IoT device can cover up to 1 hectare, Sheoran says. Another product, called Kairo, which in Greek means climate, provides data on climatic conditions.

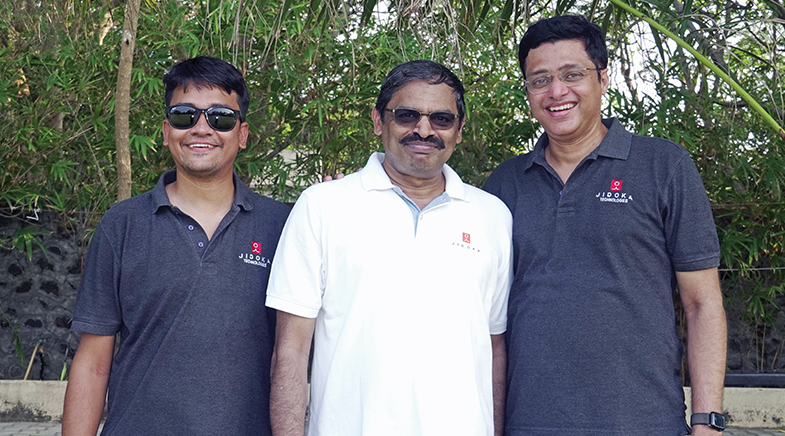

JIDOKA TECHNOLOGIES

Founders: Sekar Udayamurthy, Krishna Iyengar and Vinodh Venkatesan

Year: 2018

Big idea: Using computer vision and artificial intelligence for quality assurance in manufacturing

Krishna Iyengar faced a problem when he headed manufacturing in an auto component company. It troubled him when clients complained of quality issues in a finished product. "I was at the receiving end of customer complaints," he says.

Iyengar, who holds a dual degree in Metallurgy from the Indian Institute of Technology Madras and a PhD in Theoretical and Applied Mechanics from Cornell University, examined methods to detect and eliminate defects on the manufacturing line itself. The quest prompted him to team up with Sekar Udayamurthy, who has a Master's in Information Systems from the University of Maryland Baltimore County and has extensive experience in the information technology industry; and Mechanical Engineer Vinodh Venkatesan, who was Iyengar's colleague at the auto components company.

The three started Jidoka Technologies to automate visual inspection and quality control in manufacturing. But while quality control slowed production, faster operations resulted in more defects. The problems included high rejection rates, manual sampling inspections that slowed down manufacturing and still did not catch all defects, and outdated vision systems. Iyengar says Jidoka has developed an artificial intelligence (AI)-powered computer vision that offers accuracy rates as high as 99-99.5% with 100% inspection. The company has two products that provide cognitive product inspection and intelligent process optimisation.

One of the products, Kompass, is an AI-powered vision system that can inspect 10,000 images in a minute and help in instant decisions on rejecting defective parts. "We specialise in instantaneous decisions," he says. The system takes an image, applies AI interference, and sends a signal to reject a faulty part in the production process. "All this happens within a space of 100-150 milliseconds," he says. Jidoka utilises German cameras to capture visual images and develops its algorithms in-house. It provides a turnkey solution to its customers, which include a leading car manufacturer, a global alcoholic beverages company, and a leading biscuit-maker.

Another product, Nagare, focuses on process inspection, which leads to improvements in production system and line efficiency. He cites the example of kitting in an automobile manufacturer, where different parts required on the assembly line are put together into a box in the warehouse. Each part is numbered as per the production sequence, and even if one part is missed out during kitting, the production is affected. Jidoka utilises visual inspection, while protecting the privacy of the worker involved, and ensures that such mistakes do not occur, he says. Kompass hit the market in 2019, and Nagare in mid-2023.

YOTUH ENERGY

Founders: Dharmik Bapodara, Shaivee Malik and Vivek Mahindrakar

Year: 2022

Big idea: Developing an electric refrigeration system for trucks

While studying at the Indian Institute of Technology (IIT) Delhi, Dharmik Bapodara and his two friends built electric race cars and participated in global competitions as members of a club. This, Bapodara says, was their first brush with entrepreneurship and team-building.

Shaivee Malik and Vivek Mahindrakar were batchmates, while Bapodara was a year junior to them. Malik qualified in Biotechnology, Mahindrakar in Mechanical Engineering, and Bapodara in Production and Industrial Engineering. They wanted to work together on climate change, and realised that the cold chain was a segment that needed solutions. So, they set up Yotuh Energy – the name, derived from Sanskrit, refers to the act of cleaning – and registered the venture in Delhi before relocating to Chennai for an incubation initiative at IIT Madras, jointly offered with Daimler.

They wondered if they could develop a refrigeration system that would run on a battery, independent of the vehicle's engine. This would result in substantial savings for the operator, even though the initial cost would be higher than that of a system using the vehicle's engine to power the refrigerator. So, they developed a refrigerator powered by a lithium-ion battery and fitted it to a Tata ACE vehicle (a small commercial vehicle). It was tested in Chennai, as it transported perishables, including dairy and bakery products, as well as fruits and vegetables.

The company assembles the refrigeration system at its factory in an industrial estate in Chennai and produced its first batch of units in February 2025. "For the past one-and-a-half years, we have been running our trucks powered by our electric refrigerator," says Bapodara. They first introduced a chiller unit and then one for freezing. Their refrigerator, with a capacity of holding two tonnes, can be used in a small commercial vehicle.

PHOTO: N. RAMAKRISHNAN

(From left) Vivek Mahindrakar, Shaivee Malik and Dharmik Bapodara in front of a small commercial vehicle with an insulated container and refrigerator.

An electric refrigerator saves on fuel costs, he points out. The refrigerator can run for 6-8 hours before the battery needs to be recharged; the temperature is maintained regardless of how many times the door is opened and closed. Even if the truck breaks down, the refrigeration unit continues to function. Sensors on the truck's doors detect whenever the door is being opened or shut, and the cooling is calibrated accordingly. Yotuh Energy sells the insulated container and the refrigerator to its clients. Currently, it can assemble up to 40 units a month. It has developed two refrigeration models – one for frozen items and the other for the chiller. The battery lasts for 8-10 hours for frozen items, and longer for the chiller.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH