In the big league

-

- from Shaastra :: vol 01 edition 02 :: Jul - Aug 2021

Indian engineers are contributing to international mega science projects looking to solve the mysteries of life and space.

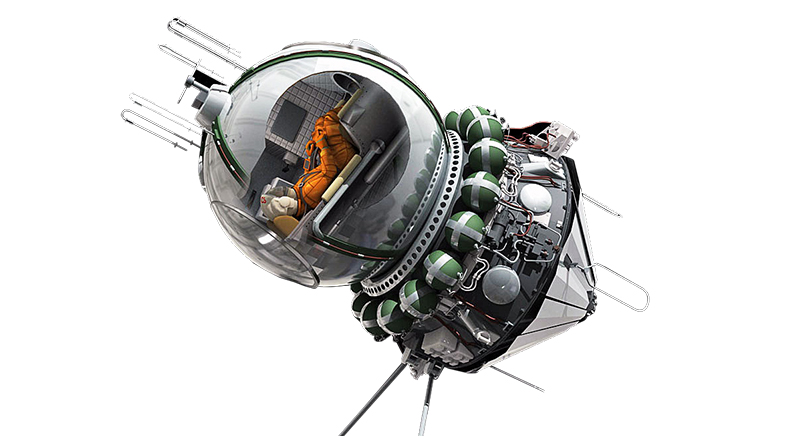

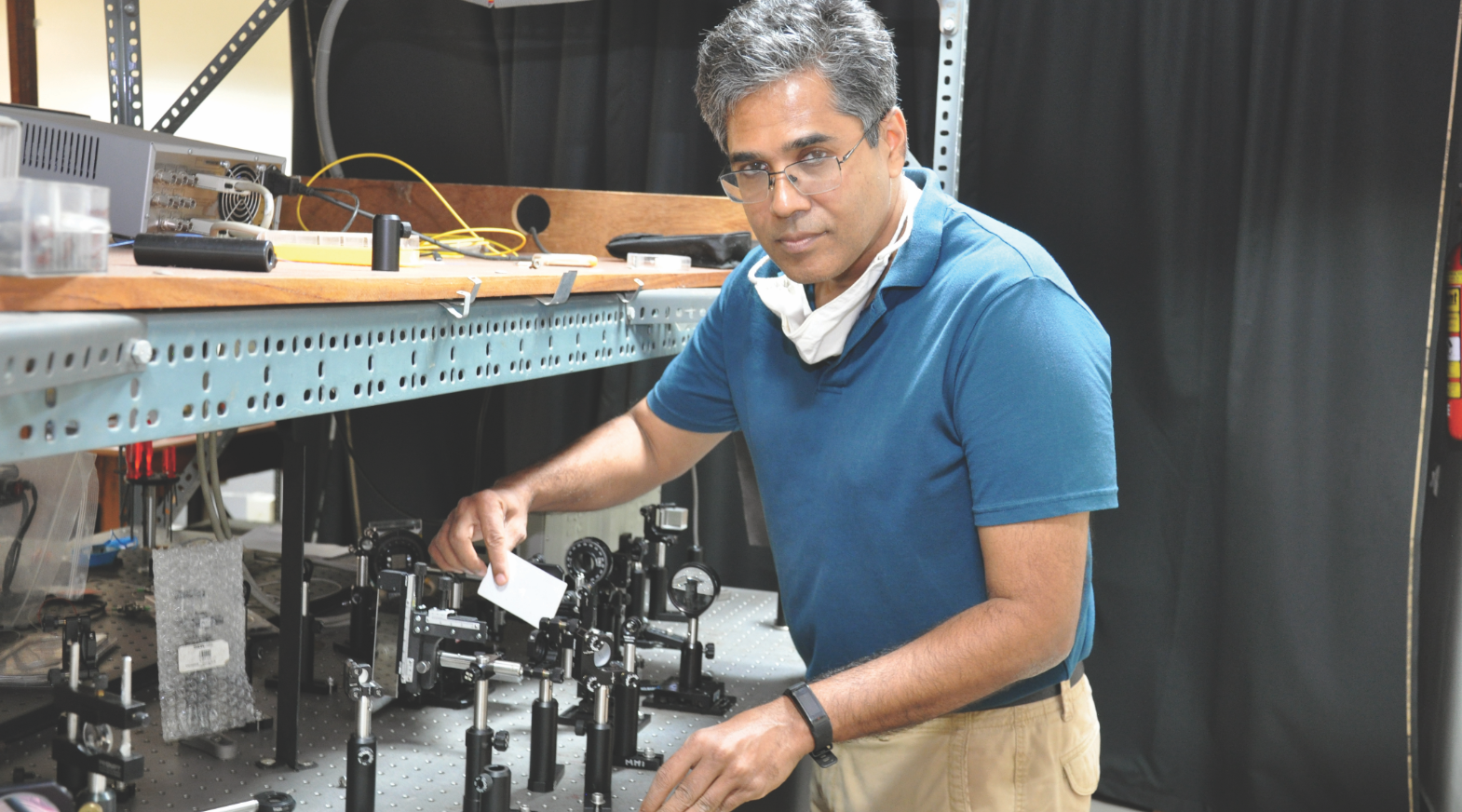

Anil Prabhakar had been working at IIT Madras for eight years when he went to see Nergis Mavalvala at the Massachusetts Institute of Technology (MIT). Prabhakar, an experimental physicist who researches on quantum optics, had been approached in 2010 by Bengaluru-based theoretical physicist Bala Iyer for interest in participation in the inchoate Indian gravitational wave project, at that time called IndIGO. Mavalvala was then part of the team that would go on to discover gravitational waves in 2015. Iyer, who had been building a team in India to participate in the gravitational wave project, thought that Mavalvala and Prabhakar should meet.

In 2010, when the two scientists met, the first phase of observations of the Laser Interferometer Gravitational-Wave Observatory (LIGO) had come to a close. Even after eight years of work with LIGO, scientists had not discovered the gravitational waves predicted by Einstein's General Theory of Relativity. Mavalvala, whose PhD research had resulted in an automated aligning system for the interferometer, was part of a team working on the Advanced LIGO, an observatory with a sensitivity three times that of the original set of instruments. Prabhakar came back to India impressed by the sophistication of LIGO's science and engineering. "I remarked at that time that if there was anybody doing photonics in the world and they were not involved in LIGO, there was something wrong," says Prabhakar. "You cannot not be involved in such a cutting-edge experiment."

Gravitational waves are ripples in space-time – space and time are taken as one entity in relativity – generated during violent events like supernova explosions or black hole mergers; the ripples travel in all directions at the speed of light, not unlike waves on the surface of a pond on which a large stone has been dropped. When they reach Earth, the waves give the planet a gentle press, squeezing it in one direction and then releasing it instantly as the waves move away. Physicists had no doubt that gravitational waves existed. But they always wondered about their ability to detect the waves.

Gravitational waves from an event a billion light-years away are extremely feeble when they reach Earth. In the interferometer that LIGO scientists have built, with two perpendicular arms each four kilometres long, one of the arms shrank in length by a billionth of a billionth of a metre when gravitational waves hit it in 2016. This shortening was measured by a small change in the interference pattern of light that travelled between the arms. Scientists had discovered gravitational waves by using the most sensitive instrument ever constructed. They are now trying to make it even more sensitive.

After he returned and LIGO-India started forming, Prabhakar set out to work on a technology that would be used in the next version of Advanced LIGO, a set of improvements that are called A+. When the third LIGO observatory – the first two are in the U.S. – is installed after 2025 at Aundha Nagnath in Maharashtra, physicists will use Prabhakar's noise-filter technique to detect the faintest of ripples in space-time. By then, a large number of scientists and engineers in India would have worked on systems of extraordinary precision for the observatory, building technologies that have wide-ranging applications in other fields in the future. "The LIGO-India project not only puts us in a respectful position in the field of gravitational wave astronomy, it also gets Indian companies exposed to work of high precision like building vacuum chambers," says LIGO-India spokesperson Tarun Souradeep.

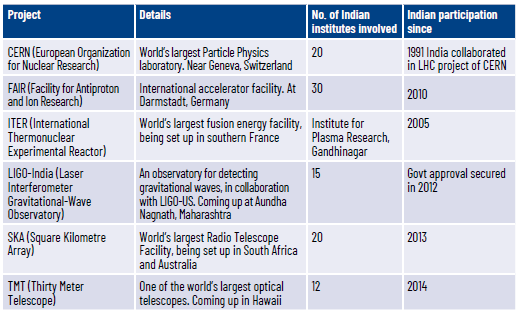

LIGO is one of the six mega – giga seems a better description – international science projects that India is participating in at the moment (see table: Reaching for the stars). The others are a fusion reactor in France, an optical telescope in Hawaii, a network of radio telescopes in multiple countries, the Large Hadron Collider (LHC) in Europe, and an antiproton research project in Germany. Along with these international projects, India has been working on its own big science project: the India-based Neutrino Observatory (see box: Observing the mysterious neutrinos). Some of these projects are in the early stages of their formation, but 90 Indian institutions, over 800 scientists and 60 companies are participating in them.

As a founding member of FAIR, India is contributing heavy-duty equipment, including ultra-high vacuum chambers and superconducting magnets.

Together, they are pushing the boundaries of the possible and developing technologies that are expected to provide spin-off benefits to a wide range of industries. "Big data, software development and technology transfer are all involved in any mega science project. They help in the overall development of the country," says Shashi Bhushan Pandey, scientist at the Aryabhatta Research Institute of Observational Sciences (ARIES) in Nainital. Add new engineering and science to big data, and we get a vision of commercial technology two decades from now.

The aim of these projects, barring the construction of the fusion reactor, is to answer fundamental questions of nature. How did the universe come into existence? How is it evolving and where will it end finally? What are the building blocks of matter? There are two ways to answer these questions, both deep. One is to investigate the smallest constituents of matter and look deep inside the atom. The other is to look far ahead into deep space and into the distant past. The first often involves creating conditions that do not exist on Earth, as a way of mimicking the conditions of the early universe. The second method involves detecting the feeblest of whispers from the early universe, to find signatures of events that happened soon after the universe was formed.

At FAIR, particles will be accelerated to high speeds to study physics – from the creation of the universe to present-day material science applications.

Both methods require the development of technologies that are too expensive or too difficult for private companies but very useful to them when ready. For Indian industry, which was secluded for long from cutting-edge research, participation in big science projects is a rite of passage and a chance to learn engineering techniques that are at least a generation ahead. Some Indian companies are exploiting the opportunity with an eye on the long-term benefits. "What we found is that Indian companies look for the future significance of their participation over financial reward," says Yashwant Gupta, director of the National Centre for Radio Astrophysics (NCRA).

SLOW AND STEADY

Participation in international science projects is not a new phenomenon for India. Indian scientists have been participating from the 1970s in projects of the European Organization for Nuclear Research (CERN), which conceived the LHC four decades ago as an underground facility to smash particles at velocities close to that of light, creating conditions that existed only at the birth of the universe. India formally joined the LHC project in 1991 and had a significant role in the project through the 1990s and the early twenty-first century, both in science and engineering, with participation from about 400 scientists.

Avasarala, a company set up in Bengaluru in 1985, had started working for the LHC in 2005. It had initially participated in the construction of a part of the collider by manufacturing 7,080 precision magnet positioning jacks on which the 27-kilometre-long circular collider tube is placed. Each of these magnets weighs 32 tonnes, but the jacks maintain the position of the magnets to an accuracy of 0.05 millimetres even when they are subject to forces all around. Avasarala’s work on the LHC brought more work for the company: for the telescope in Hawaii, the fusion reactor in France, and the antiproton experimental facility in Germany.

The Indian participation in the LHC project has been mainly for its two large detectors: A Large Ion Collider Experiment (ALICE) and the Compact Muon Solenoid (CMS). Detecting a new particle whizzing around at the speed of light in a sea of other particles is not an easy task. To make things more difficult, some of these exotic particles are short-lived. CERN needed sensitive detectors, and its scientists invented one in 1997. Called the gas electron multiplier, it has become a key component at the LHC for detecting charged particles. The detectors are made at CERN itself, and only a small number of companies have the capability to make it at the required precision.

In 2015, scientists at the Bhabha Atomic Research Centre (BARC) asked a small Bengaluru-based company, Micropack, whether it was interested in making the gas electron multiplier for CERN. Micropack, which has a turnover of ₹67 crore now, made printed circuit boards for the military that required high reliability. This background did not automatically qualify the company for LHC; making the gas electron multiplier required a high level of precision engineering. One of the difficult tasks included making a 50-micron thick – one micron is a millionth of a metre – polyamide film that has to be punctuated uniformly with 70-micron holes. A square piece of foil of a side of 300 millimetres would require hundreds of thousands of such holes, which are not drilled but chemically fabricated.

In 2020, 144 gas electron multiplier detectors made by Micropack were installed at the LHC, and the company is now making a larger set of detectors to be installed in 2022. Meanwhile, it is searching for other applications for the technology. It is working with Delhi University to use the gas electron multiplier technology in medicine to detect cancer and focus a beam for treatment. "We do not quite know about all our opportunities," says Pradeep Menon, chief operating officer of Micropack. "Application of this technology in medicine is not proven yet."

Participation in the LIGO-India project puts Indian scientists and Indian companies on the frontlines of gravitational wave astronomy.

More than 20 Indian institutions and an equal number of companies now work for the LHC. About 500 km from Geneva, where the LHC is located, another set of scientists are involved in an experiment to create particles that exist mostly in the depths of space. Called a universe in the laboratory, the Facility for Antiproton and Ion Research (FAIR) at Darmstadt in Germany is another accelerator – a device that accelerates particles to high speeds – but with a scientific purpose different from the LHC. It aims to study physics, starting from the creation of the universe to present-day material science applications.

For example, one of its experiments will create on a small scale the high temperatures and pressures that exist inside stars and study how nuclei of atoms are cooked inside them. Another experiment will create antiprotons, the antiparticle of a proton, as a way of understanding mass and the strong force that binds protons and neutrons together in the atomic nucleus. A third project will create the extreme conditions, for a fleeting instant, found inside neutron stars. The fourth experiment at FAIR is to look at applications of atomic and plasma physics. The facility will have the infrastructure to create ten million particle collisions per second, which is higher than any existing or planned accelerator in the world. Construction of the facility began in 2017.

India is a founding member of FAIR and holds 3.6% of its current shares. The country is supposed to contribute around €36 million, of which €9 million will be in cash and the remaining €27 million as equipment. In one of its early projects, the Variable Energy Cyclotron Centre (VECC) in Kolkata, with collaboration from the Electronics Corporation of India Limited (ECIL), designed and produced a high-current and stable power converter. It had taken the institution three years to conceptualise and seven years to design and manufacture from scratch. "The converter required a lot of non-trivial R&D," says Sibaji Raha, former Director of the Kolkata-based Bose Institute and Chair of the FAIR India Scientific Council. The technology for such converters can be useful in electric car batteries or future nuclear power plants.

For FAIR, India is also providing ultra-high vacuum chambers, superconducting magnets and power cables. Around 30 institutes are participating in FAIR, including BARC in Mumbai; the University of Calcutta; and Aligarh Muslim University. One of the beam catchers – a piece of equipment that absorbs the energy of particles – of FAIR was designed by the Bose Institute and the Central Mechanical Engineering Research Institute (CMERI) in Durgapur. Equipment designed in India are usually manufactured in India, and so it is an opportunity for Indian companies to manufacture the beam catcher. Bose Institute and VECC also designed the multipole magnets for the experiment to study atomic nuclei formation in stars. The two physics projects – LHC and FAIR – have significantly improved accelerator science and engineering in India. Particle accelerator technology has direct relevance for cancer treatment. "We need to learn the technology once, and then we can copy it in every state," says Tapan Kumar Nayak, former deputy spokesperson of ALICE collaboration, CERN.

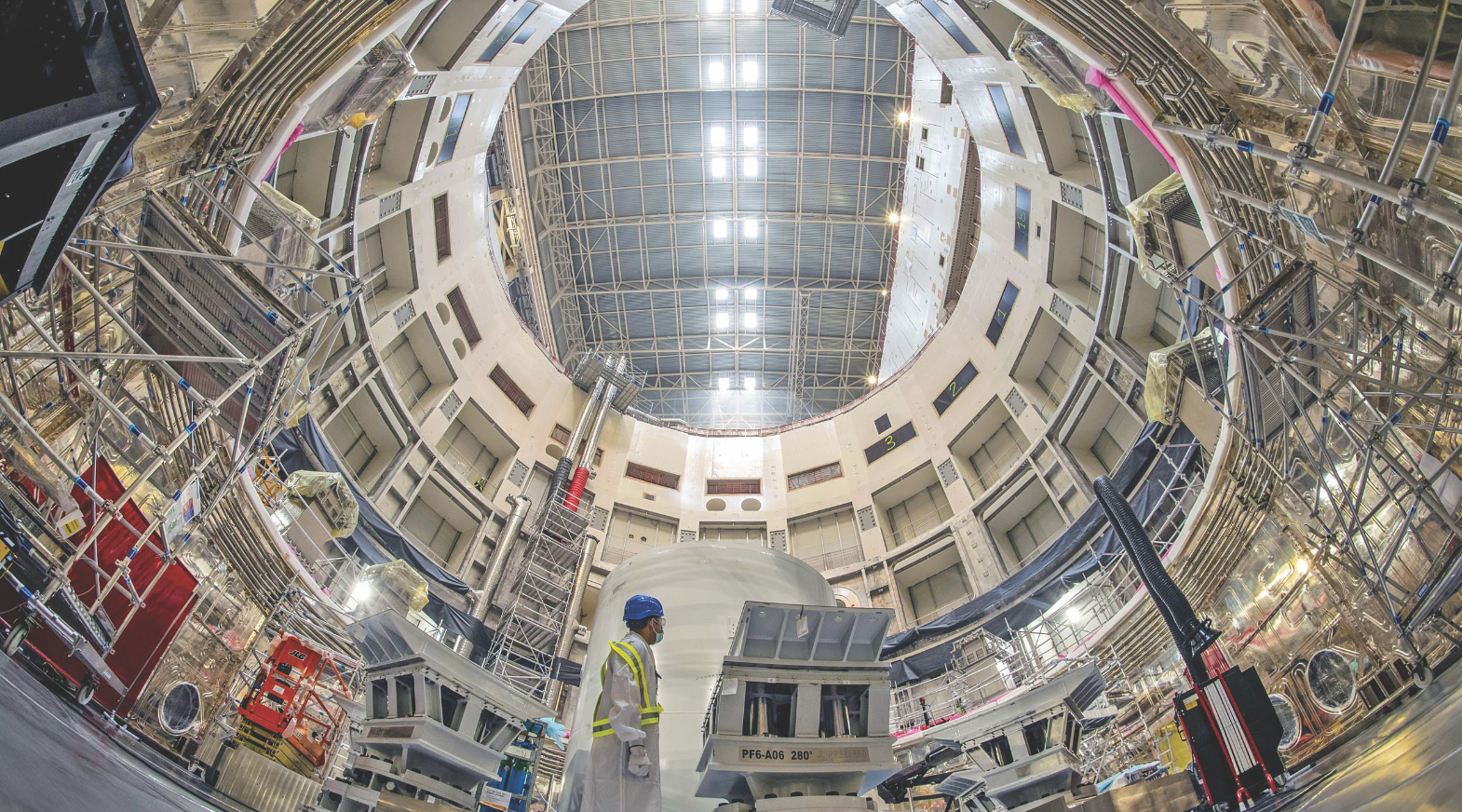

While FAIR tries to create on Earth tiny representations of stars, scientists from seven countries have been trying to make stars on a much larger scale. The International Thermonuclear Experimental Reactor (ITER) at Saint-Paul-lez-Durance in France is a mini-star that will use atomic fusion to produce electricity. It is contained in a reactor called Tokamak, which magnetically confines the hot plasma in a region shaped like a torus.

India is represented in ITER by a single institution: the Institute for Plasma Research (IPR), in Gandhinagar, under the Atomic Energy Commission. India became the seventh full partner of ITER in December 2005 and contributes 9.1% of the total project cost of around €20 billion. All partner countries are to get full access to its knowledge and information irrespective of their share of the project.

The fusion reaction that produces the energy happens at a temperature of 150 to 300 million degrees Celsius. The reactor is surrounded by a 3,850-tonne cryostat, which encloses the world’s largest vacuum chamber, and which has to be maintained at a temperature of a few thousand degrees Celsius. Larsen & Toubro had taken up the task of designing and manufacturing the 30-metre-wide and 30-metre-high cryostat from scratch, doing the detailed engineering, metallurgy, welding technology, fabrication technology, forming, machining, quality control, and training of the people involved in the project.

The cryostat was built in 54 modules, integrated into four large assemblies, and taken to the main reactor for installation. The company had to do one kilometre of full-penetration welding of joints, followed by several hundred metres of welding to assemble the cryostat sections in the Tokamak Pit. The lower part of the cryostat had to be installed in the reactor with a precision level of three millimetres. The virtual digital assemblies, software for distortions control and special welding techniques developed for the ITER project are now being used by L&T in other commercial projects.

STAR-MAKING TO STAR-GAZING

The largest optical telescope in India is the 3.6-metre optical telescope at ARIES in Nainital, which began observations in 2016. The previous largest was a 2.3-metre telescope at the Vainu Bappu Observatory in Kavalur, Tamil Nadu. Both are small in contemporary optical astronomy: there are 13 telescopes in the world with a mirror diameter of over eight metres. And there are at least three telescopes under construction with a diameter of more than 30 metres. When ready, these telescopes would leave Indian optical astronomy far behind. Fortunately, India got to participate in one of them: the Thirty Meter Telescope (TMT) in Hawaii.

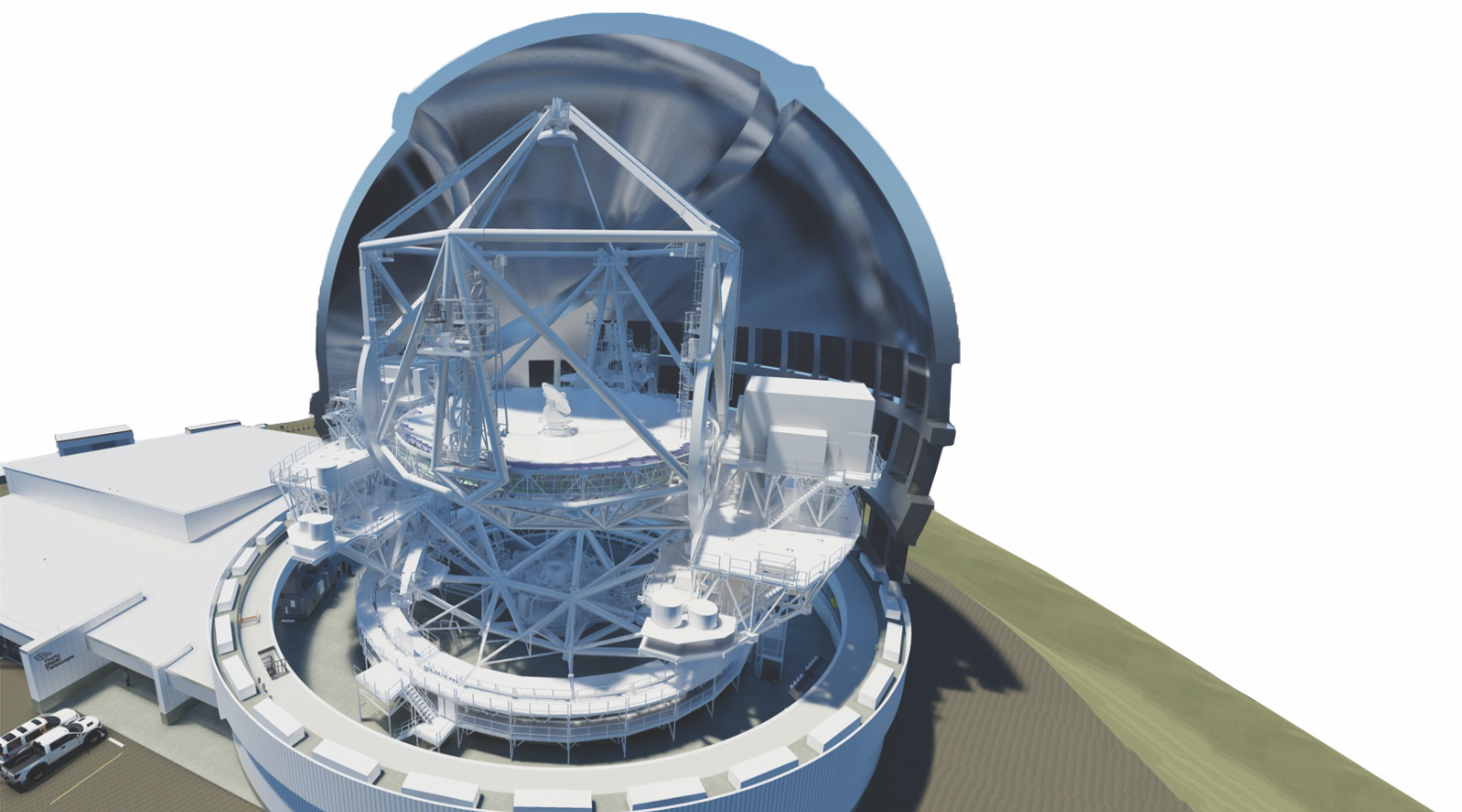

The TMT is being built by astronomers from India, Canada, China, Japan, and the U.S. Like all other international projects, it will push the envelope of technology by a generation or two. It will have a 121-tonne primary mirror comprising 492 hexagonal-shaped mirrors, each 1.44 m across and 45 mm in thickness. All these hexagonal mirrors are to be mounted on a complex optomechanical system called segment support assembly, many of which are to be made by L&T. The segment support assembly aligns the mirrors to a precision of four-billionths of a metre, and this accuracy is maintained by actuators that bring the pieces back in alignment when stressed by external forces. "The accuracy level of the instrument sounds crazy," said J.D. Patil, Whole-time director of L&T.

India-TMT will provide 3,284 edge sensors required for the primary mirror segments, made by General Optics (Asia) Ltd (GOAL), Puducherry, and the Bengaluru-based Optics & Allied Engineering Pvt Ltd. Other than hardware components, Indian companies are also working in telescope control software. TMT will use adaptive optics to correct the effects of atmospheric turbulence for improved images, roughly a thousand times a second, using an extraordinarily complex technology that has now found applications in medical imaging. India-TMT is also responsible for manufacturing all the 1,526 actuators required for the project, which will bring the mirrors back in alignment after deflection due to natural events. A Jamshedpur-based company, Indo-Danish Tool Room (IDTR), made prototypes of the actuators that work to a precision of four-billionths of a metre.

Of the 492 mirrors of the telescope, 84 are being made by the TMT Optics Fabrication Facility (ITOFF) on the campus of the Indian Institute of Astrophysics. This facility was specially developed for the TMT project. Since highly polished mirrors are an integral part of many devices, the facility is expected to be used frequently in the future. The telescope uses stress mirror polishing, a new technique that uses controlled stresses to coax mirrors into the required shapes. "I think we are in a big game because many countries may ask us for the mirrors in the near future," said B. Eswar Reddy, Director, India-TMT.

Observing the mysterious neutrinos

INO will help understand 'extreme events' in the universe.

In 2001, three physicists met at the Saha Institute of Nuclear Physics (SINP) in Kolkata to discuss the possibility of a neutrino observatory. They talked all day and over beer at dinner, often about failed projects and why things didn't work in India. "After the dinner, with glasses of beer, we decided we had enough talk on failures, now let's together make it happen," says Naba Kumar Mondal, one of the three scientists and Raja Ramanna Fellow at SINP.

Their ideas morphed into the ₹1,500-crore India-based Neutrino Observatory. Neutrinos are particles of negligible but non-zero mass; some 100 trillion of them stream through the earth – and our bodies – every second. Neutrinos are among the most mysterious particles known to physicists. Their precise mass is not known. They travel in straight lines for billions of years, not stopping to interact with the matter they encounter. Because of this feature, they are one of the best objects to study to understand events in the universe. Especially the extreme events.

After a long search, scientists chose Pottipuram, in a mountainous region in Theni district of Tamil Nadu as the INO site. It was opposed by environmental activists and local politicians, but the Union Cabinet cleared it in 2015. Opposition to the project continues, but scientists are confident of starting the project soon.

The proposed lab is around a kilometre under the mountain and will have three inter-connected cabins that will house three experiments. A two-kilometre-long motorable tunnel will connect the cabins to the outside. This experiment will consist of a gigantic 51-kiloton iron calorimeter with 30,000 fast and highly sensitive particle detectors, which measure the energy of the particle as it passes through each layer.

Several Indian companies are contributing to the project. Saint-Gobain, based near Chennai, is making the glass resistive plates for the calorimeter. The glass sheets for the calorimeter were coated with a special paint developed by Kansai Nerolac.

The TMT is a giant leap for the global astronomy community, and especially for Indian optical astronomers. On the other hand, the Square Kilometre Array (SKA) grew partly out of ideas from Indian astronomers. In 1991, Govind Swarup of NCRA-TIFR proposed a large, next-generation radio telescope, and suggested it be named the International Telescope for Radio Astronomy (ITRA); in a paper published in Current Science journal that year, Swarup had noted, "itra means perfume or essence in Hindustani". That idea has since morphed into the SKA. It consists of multiple dishes in several countries with a combined area of one square kilometre.

Most of the dishes will be at South Africa's Karoo region and Western Australia's Murchison Shire, two of the most remote and quiet locations on Earth. The unprecedented combined sensitivity of the SKA dishes, spread over hundreds of kilometres in these locations, will give astronomers insight into the formation and evolution of the first stars and galaxies after the Big Bang, the role of cosmic magnetism, the nature of gravity and dark energy, and so on. Around 20 institutions in India are collaborating on the project, with NCRA as the nodal institute.

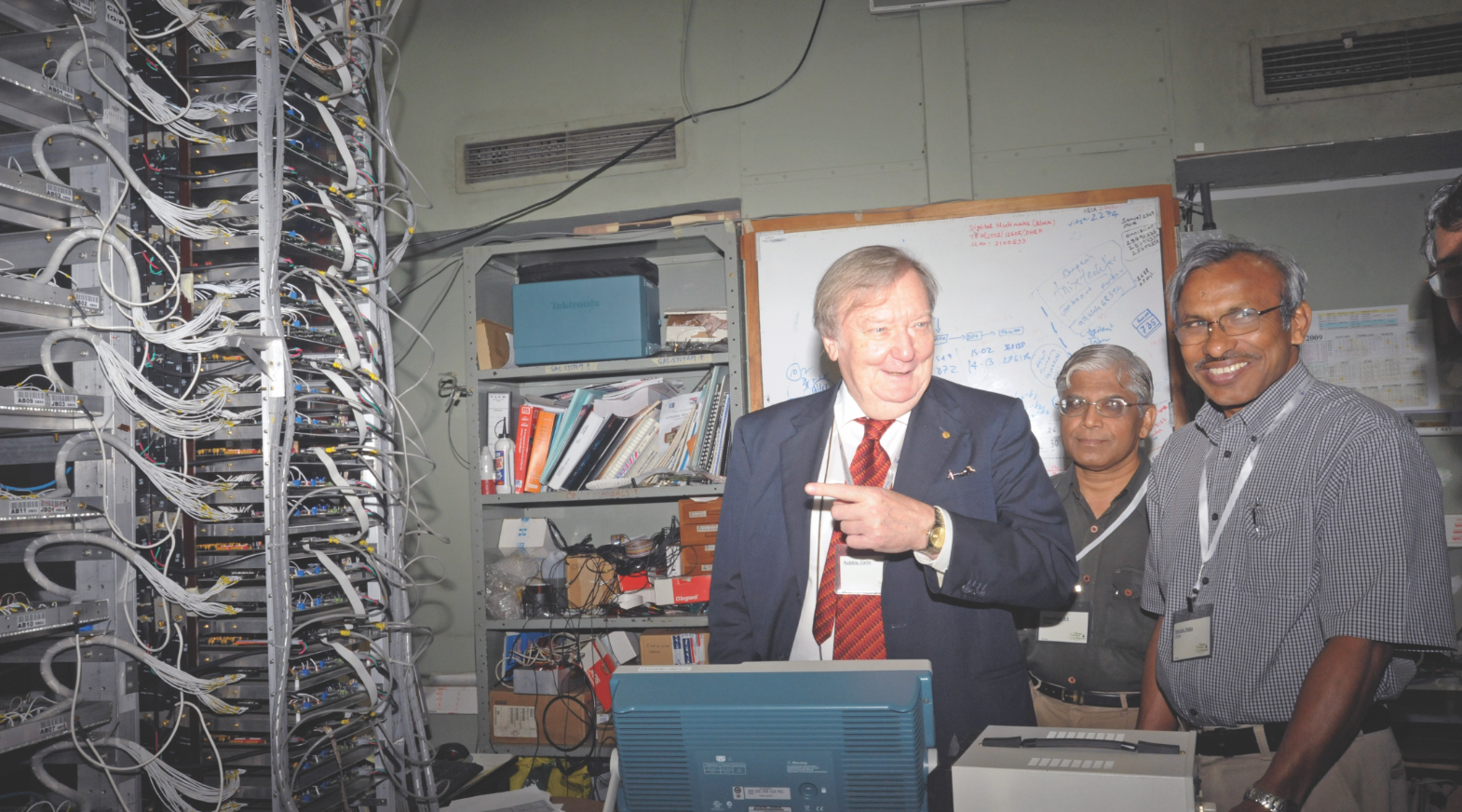

The leading Indian contribution for the project will be the Telescope Manager (TM), being developed with assistance from two software companies: TCS and Persistent Systems. Persistent had earlier developed software for the upgraded Giant Metrewave Radio Telescope near Pune. The telescope manager will control thousands of receptors that will, in turn, generate petabytes of data. In India, the SKA will also trigger the development of antennae, low-noise electronics, analog and digital signal processing, high-speed computing, massive data storage, image processing, data mining, and large software systems.

Astronomers from India, Canada, China, Japan, and the U.S. are collaborating on the TMT project, which will push the envelope of technology by a generation or more.

Cutting-edge science projects have always driven the development of technology that is out of the reach of private companies. Big international projects involve engineering research at every stage, projects that lead to an avalanche of benefits to the world of industry later. The technology that Prabhakar develops at IIT Madras for LIGO, a method to squeeze light waves to reduce the uncertainty of measurements, will have direct applications to medical imaging. A decade from now, an Indian company could use that technology to build a sophisticated global business.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH