A Kevlar rival in the making?

-

- from Shaastra :: vol 02 issue 06 :: Nov - Dec 2023

Scientists look to collagen for making a strong polymer.

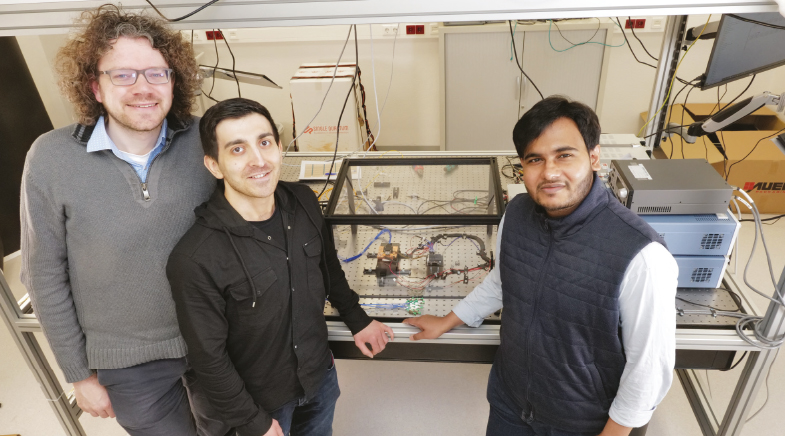

Inspired by collagen, the structural protein that makes up nearly a third of the human body's dry weight, researchers at the Indian Institute of Science Education and Research Thiruvananthapuram (IISER TVM) have synthesised a biopolymer mimic. The polymer can rival Kevlar, a synthetic fibre known for its high strength that is used in making bullet-proof vests, combat helmets and ballistic face masks.

Found in bone, skin, muscles and cartilage, collagen's triple helical structure and the arrangement of its constituent amino acids make it a very strong biological polymer. "Collagen is called biological steel. Ants can carry 5,000 times their weight because of collagen present in their legs," says K.M. Sureshan, Professor of Chemistry at IISER TVM, who led the research. "Collagen is a protein consisting of repeating tripeptide: glycine, proline and any other amino acid. We have taken a similar sequence of amino acids for making this crystalline material." The work (bit.ly/crystallinepolymer) was published in Angewandte Chemie on October 20.

To synthesise this strong yet light-weight crystalline polymer, which can bear 1.6 million times its weight, the researchers followed the helical topology of collagen. The repeating unit (monomer) of this polymer was made with three amino acids, including glycine and proline. The monomers were then chemically modified and aligned in a crystal.

To synthesise this strong yet light-weight crystalline polymer, which can bear 1.6 million times its weight, the researchers followed the structural arrangement of collagen.

Next, scientists used temperature to link the monomers via a process called topochemical polymerisation. "Typically, polymerisation is done in solutions. You need catalysts and... a solvent. In this case, we take monomers and heat them," says Sureshan. Another advantage of the method is ease of purification; there is no need to remove unreacted monomers and catalysts.

"Generally, it is extremely difficult to obtain polymers with high crystallinity," says C. Malla Reddy of IISER Kolkata, who was not involved in the work. "Sureshan's group developed a strategy to do this using chemical transformation of pre-aligned monomers into polymers via single-crystal-to-single-crystal transformation by heating."

Such polymerisation in single crystals should lead to improved mechanical strength as molecules get connected via much stronger covalent bonds. But, in earlier studies, Sureshan and his team didn't see much improvement in the mechanical properties due to a counter effect – the formation of defects due to increased strain caused by chemical reactions.

"In this new study, they could overcome this limitation by cleverly using amino acid units that are present in collagen. It appears that these monomers are able to minimise the stress and defects," says Reddy.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH