Clearing the air

-

- from Shaastra :: vol 04 issue 02 :: Mar 2025

A trimetallic nanocatalyst promises to effectively convert CO2 into carbon monoxide — at top speed!

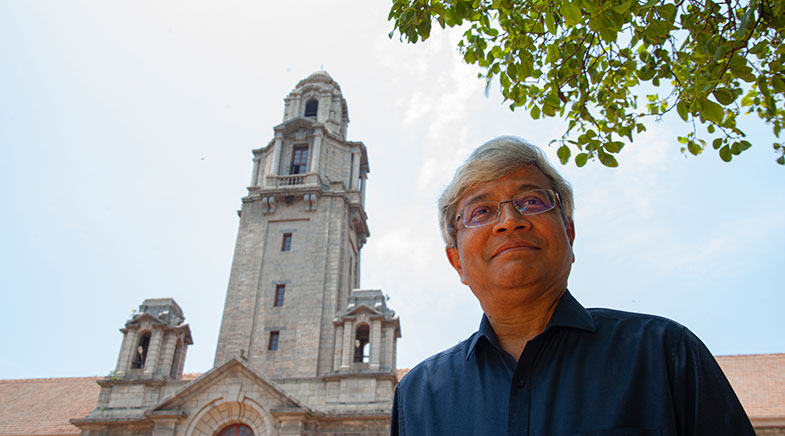

Vivek Polshettiwar had a mission. The Professor of Chemistry at the Tata Institute of Fundamental Research (TIFR) Mumbai wanted to develop nanocatalysts that could turn carbon dioxide (CO2) spewed into the atmosphere by industries into valuable chemicals and fuels. Such technologies, however, were far from perfect and had so far yielded little.

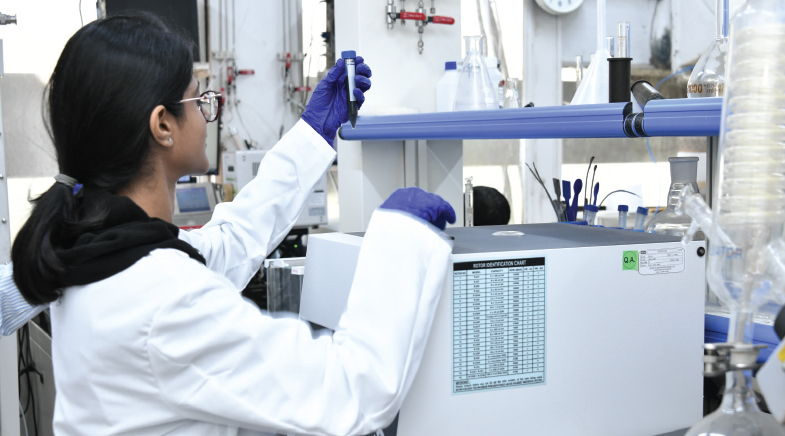

Polshettiwar's team at TIFR, though, has developed a novel trimetallic nanocatalyst which can convert CO2 into carbon monoxide (CO) at a rate nine times better than the best reported so far. The catalyst is called trimetallic because each of the nanoparticles present has three metals – nickel, copper and zinc – in a certain ratio. The catalyst is synthesised by mounting these trimetallic nanoparticles on a support made of ceria (cerium oxide). The scientists found that the catalyst is stable and does not degrade even after 100 hours. "It's the best reported work from my group in the last 12 years," says Polshettiwar, who came up with the idea of the nanocatalyst three years ago.

Nickel, copper and zinc have different electronegativity, the tendency of an atom or a functional group to attract electrons towards it. "What happens then is that one metal pulls electrons from another one. For instance, nickel pulls electrons from copper, and copper from zinc. And ceria, which acts as a support, is also electron-rich and thus yields electrons to all these metals," Polshettiwar explains.

The catalyst is capable of producing more than 49,000 millimoles of CO per gram of catalyst in an hour, a nine-fold increase over previously reported catalysts, and has an extremely high CO selectivity of 99%, the scientists recently reported in the journal PNAS (bit.ly/Polshettiwar). The catalyst's extraordinary efficiency, among other things, is enabled by the creation of a strong metal-support interaction (SMSI) between trimetallic sites and defects in ceria. Such 'defects' are created by taking oxygen atoms from ceria, prompting it to absorb CO2 molecules. Once the CO2 adsorption takes place, the trimetallic catalyst gets into the picture and, with the help of hydrogen, breaks CO2 into CO and oxygen, says Polshettiwar. The ideal temperature range for better CO production is around 650° Celsius.

PAST ISSUES - Free to Read

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH