Drop by inky drop

-

- from Shaastra :: vol 04 issue 08 :: Sep 2025

Made-in-India bioinks may give 3D bioprinting research a leg up.

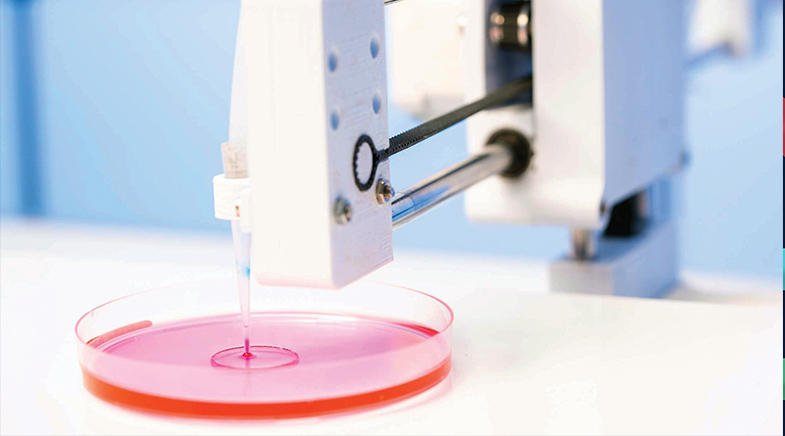

In 2016, researchers at the Kerala-based Sree Chitra Tirunal Institute for Medical Sciences and Technology set out to create a three-dimensional (3D) model of liver tissue. The aim was to build a system on which to test drugs for liver toxicity. Such models are intended to reduce or replace the use of laboratory animals in testing and potentially generate more human-relevant data (See 'Of mice and men').

The team was led by tissue engineer Anil Kumar P.R., head of the institute's tissue culture division. A key team member was Shiny Velayudhan, a polymer technologist with a focus on biomedical applications. The researchers chose novel 3D bioprinting as a method. This allowed them to deposit cells precisely, layer by layer, in a desired arrangement. Such bioprinted constructs mimic the structure and function of human tissue, in this case, the liver. Automation gives control over the process.

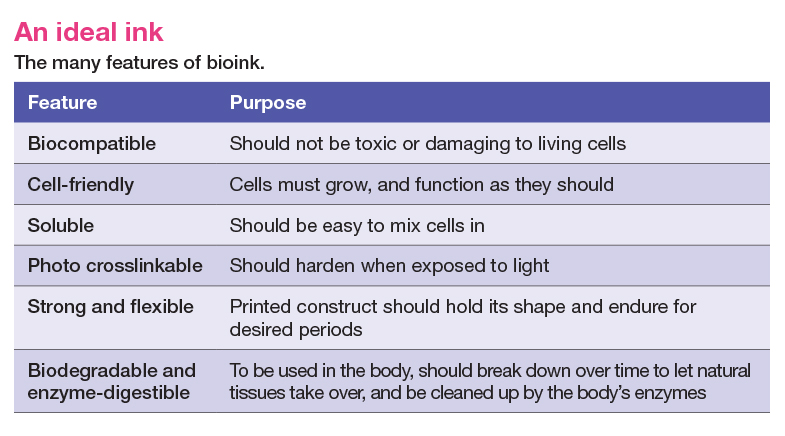

The ink is typically a mix of biomaterials, the relevant cells, and a culture medium. Standard biopolymers, such as alginate, extracted from seaweed or algae, and collagen taken from animal skin or bones, form the base. These are fine-tuned further for a specific purpose. This so-called 'bioink' is critical to 3D bioprinting experiments and must have desirable features for successful printing (See box: 'An Ideal Ink').

Kumar's team chose Gelatin Methacrylamide (GelMA), a type of gelatin that is modified for bioprinting and widely used for its cell- and print-friendly properties. By 2020, not only did they have a working drug testing model, but also a novel bioink that best suited their purpose. It had cleared a battery of tests and was also found suitable for printing brain cells and skin. Researchers expose printed constructs to ultraviolet (UV) light for polymerisation or to harden them — a process known as photo crosslinking. This novel formulation was made UV-protective without compromising the crosslinking process.

Meanwhile, Jikku Jose, founder of the Kochi-based start-up Scire Science, had become acquainted with Kumar. Scire has its own 3D cell culture lab with an interest in 3D bioprinting and biomaterials. The lab also offers services and trains young researchers in the field. They got talking, and Jose's interest was piqued. In November 2024, Scire announced its commercial rollout of the ink, branded Scire Chitra GelMA-UVS Bioink, under licence from Sree Chitra. They claim this is India's first indigenous, commercialised, and patented bioink. Customers of the ink include biotech and hospital research labs, and bioprinter manufacturers who want to bundle it with their machine, says Jose.

The Scire Chitra ink is supplied in a sterilised, freeze-dried powder form to be mixed with culture medium and cells.

The ink is supplied in a sterilised, freeze-dried powder form to be mixed with culture medium and cells at the time of use. Unlike some imported, pre-mixed formulations, it does not need a cold chain for transport and storage. It also has a longer shelf life. Jose wants Scire to make a range of biomaterials and inks readily available to researchers.

FOR WIDESPREAD USE

Globally, a number of potentially pathbreaking applications are being studied using 3D bioprinting. 3D-printed disease models for research and drug testing could spare lab animals. 3D-printed skin grafts could speed up wound healing, and such tissues or organs could one day be routinely transplanted into humans for repair or replacement. In India, outside the private sector, 3D cell culture research is still limited to a clutch of elite institutions. The investment to build and maintain contamination-free clean rooms to grow and handle cells, and the cost and logistical challenges of procuring inputs, act as deterrents to more widespread use.

When it comes to bioinks, the major suppliers are based in developed countries. Their principal customers are well-funded research programmes in the West, and the inks are priced accordingly, says Suhridh Sundaram, Chief Operating Officer of the Bengaluru-based bioprinter manufacturing and services company Avay Biosciences. "But what's viable in one region isn't so in another."

Avay has also started producing bioinks for researchers. This has yielded significant cost savings. For the price it would pay an imported source for bioinks to perform a set of experiments, it can do both — make the inks and also conduct those experiments.

A gram of a bioink from a leading European supplier could cost ₹30,000-40,000, and it does not go very far, says Krishna Santosh, Lead Bioengineer at Bengaluru's bioprinter company Sytolab. Researchers in Western countries have a budget to procure these. In India, where 3D bioprinting is still a novel technology, they find it more cost-effective to formulate their inks by sourcing the base materials, he says. But this adds two to three years of research to the timeline. "Researchers should be worrying about the applications and not the ink." Krishna recently tested Scire's bioink for compatibility with Sytolab's bioprinter and has included it in its offerings to customers. "We want to create an ecosystem and not just sell the hardware," he says.

In academia, it is common practice to set students in postgraduate and PhD programmes to work on formulating the inks, says Suhridh. "The expectation is that they should learn, and there is no time pressure." However, if translational research and technology transfer to industry are the goals, there is value in a standardised source of ink that has undergone quality checks and controls on every batch that cannot be done at the lab level, he says. This would reduce the variability in experiments. "Industry requires repeatability." A bioink, even if it is for research, must undergo a battery of tests to qualify it as a printable material.

A SMALL BEGINNING

Can indigenously produced bioinks give a boost to the 3D-bioprinting sector? Bioinks are a well-studied area, and there is plenty of published research, says Suhridh. But they have to be tested and optimised for key parameters such as their ability to support cell growth and print durable structures. For commercial bioinks, transport and storage conditions have to be validated.

The field is niche, and the market for such bioinks has just started to develop. But this is set to change, Krishna asserts. The Food and Drug Administration of the U.S. has begun to approve drugs tested on 3D bio-printed models. This will encourage more researchers to move to culturing cells in three dimensions. And the day when drug testing in animals is entirely banned may come sooner than expected, he says. "Bioprinting will be the only option."

At Sree Chitra, more research will follow to scale up and validate the bioprinted liver toxicity test system for regulatory approval, says Kumar. His team is now studying liver constructs bioprinted using its GelMA for transplantation. These experiments could lead to the evaluation of the bioink for use inside humans, says Kumar. A collaboration with industry is being looked at as this would need continuous funding, he says.

To print anything that is put into humans, bioinks have to go through further testing, including in humans. They will also have to be made in a facility that follows standards for good manufacturing practices, which needs additional capital, says Chaitanya Doshi, Chief Executive Officer of Kore Additive Manufacturing and Medical Reconstruction, a start-up incubated at the Indian Institute of Technology Bombay. Kore manufactures and sells base materials such as chitosan and collagen and is testing its own bioinks made from these materials. Though Kore's biomaterials are currently meant for research, its goal is to make transplantable organs.

Regenerative medicine is the holy grail of 3D bioprinting. Says Suhridh of Avay: "The biggest impact would be felt if we could translate this into a use case that positively impacts someone's life."

See also:

Patching skin with bioink

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH