Helping hands

-

- from Shaastra :: vol 02 issue 05 :: Sep - Oct 2023

Start-ups are making life easier – with bionic hands, SoCs and recycled metal.

Metastable Materials

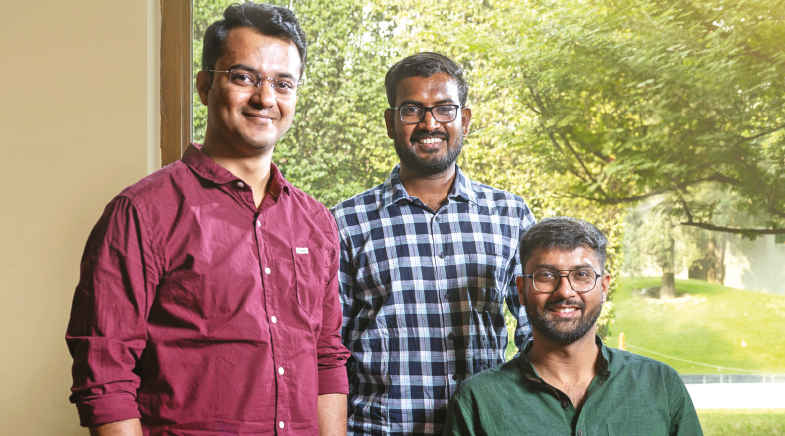

Founders: Shubham Vishvakarma, Saurav Goyal and Manikumar Uppala

Year: 2021

Big idea: Extracting ores from recycled lithium-ion batteries

There is value in waste, the three alumni of Indian Institute of Technology Roorkee realised. So, Shubham Vishvakarma, Saurav Goyal and Manikumar Uppala decided to do something about old batteries, which were treated as waste. The growth in electric vehicles meant that disposing of lithium-ion batteries was going to pose a huge challenge. The primary focus so far was on the hazardous nature of the dumped batteries. The three men, however, looked at batteries not as waste that had to be eliminated but from which valuable ores could be extracted.

This led to Metastable Materials, a start-up they set up in Bengaluru two years ago to recycle lithium-ion batteries and extract ores from them. "At Metastable, we treat the wastes as ores, just like any other ore of critical metals such as lithium, cobalt and nickel. A typical lithium or cobalt ore has less than 1% concentration (of the metal). In contrast, lithium-ion batteries contain up to 7% of lithium carbonate and up to 13% of cobalt, making them the richest ores of these metals," says Metastable Co-founder Goyal.

The recycling industry, he adds, is plagued by supply chain constraints, high processing costs and issues over scaling. Metastable has developed a proprietary technology, Integrated Carbothermal Reduction, which is a chemical-free process designed to extract metals from discarded lithium-ion cells and batteries. It takes the dead cells and batteries as input and produces copper, aluminium, cobalt and nickel in their natural forms, while lithium is produced as a carbonate. The total yield of the process is over 90%, Goyal says.

Metastable, which has raised seed funding, is in the process of commissioning a 1,500-tonne-per-year pilot facility near Bengaluru. This, he believes, will meet 4-6% of India's current recycling needs. The company seeks to prove the technology and scale; and pitch India as a global leader in recycling lithium-ion batteries. It is in discussions with clients across industries.

Besides being a key ingredient in lithium-ion batteries, lithium is also used in lubricants. Nickel's primary use is in stainless steel, which accounts for almost two-thirds of the global nickel production. The company's client base will include companies from a chemical manufacturing background to steel and those making alloys.

According to Goyal, producing metals in their raw form gives Metastable and its clients the flexibility to use them as per their requirements. It helps the company focus on the circular economy, not just at the product level but at the level of metals. The primary use of copper, aluminium, cobalt and nickel is not in lithium-ion batteries. They have been used for ages in applications such as electrical wires, alloys and steel, Goyal adds.

PAST ISSUES - Free to Read

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH