New ideas: sell, cell, gel

-

- from Shaastra :: vol 04 issue 02 :: Mar 2025

Start-ups focus on production, insect detection and solar panels.

MACHINE MAZE

Founder: Arun Ramu and S. Yogeshwaran

Year: 2021

Big idea: A platform to connect global OEMs and Indian SMEs

Arun Ramu used to wonder what India could do to boost its manufacturing sector. During his stints in multinational companies in India — heading their research or engineering divisions — he had gathered that companies were willing to get their products engineered in India but wanted them manufactured elsewhere.

Ramu realised that India's small and medium enterprises (SMEs), which employ thousands of people and have idle capacity, could help in this endeavour. Original equipment manufacturers (OEMs), he reckoned, could use SMEs to make their products in India. However, SMEs in India have their own challenges, including access to the latest engineering and software tools, and working capital availability. "Machine Maze was born out of the need to solve problems for SMEs," says Ramu, who has a Master's in mechanical engineering.

The company is a contract manufacturing aggregator and has a network of over 450 manufacturing partners across the country along 26 core metal manufacturing processes, he adds. It focuses on five industry verticals: power and transmission; oil and gas; last-mile logistics as in e-vehicles; aerospace; and industrial pumps and motors. It has built a proprietary technology platform on which an OEM places its requirements and orders. Machine Maze then identifies the SME that will produce the required parts for the OEM concerned. The start-up, according to Ramu, ensures quality and meets delivery schedules.

The company is a contract manufacturing aggregator and has a network of over 450 manufacturing partners across the country.

The company processes the engineering drawings and procures raw materials, which are handed over to the SME partner, and once a part is produced, it is delivered to the OEM. Every SME partner's capability and capacity are mapped. "We break down the manufacturing requirements that come, discover prices in the market, figure out the right vendor to give it to, support the vendor with working capital and with engineering – because we run all 3D-modelling software – and we enable them to manufacture," he says.

Machine Maze, he cites as an example, has built the chassis of logistics vehicles to be shipped to Germany. "It is (made with) over 300 parts. Can you imagine an SME dealing with 300 parts and more than 500 drawings, putting things together and figuring out how to do it?" OEMs have a huge cost advantage in getting the parts produced in India. The company gets its revenues from the OEMs, for which it has so far made over 4.5 million parts.

TREBIRTH

Founders: Mukund Choudhary and Maitree Dedhia

Year: 2021

Big idea: A non-invasive technology to detect stem borers in plants

Mukund Choudhary opted for the road not taken after a B.Tech in computer science. He took up a project with Digital Impact Square (DISQ), the social innovation initiative of Tata Consultancy Services (TCS), where he worked on the problem posed by stem borers in vineyards in Nashik, Maharashtra. The insects hollow out the insides of plants, depriving them of nutrients and water. They affect various plants, including grapes, mangoes, coffee, and pomegranates.

Choudhary says he understood the enormity of the problem caused by stem borers and also realised that there was hardly any technological solution to it. By the time a farmer notices the infestation symptoms, it is too late to take remedial measures, and the plant has to be hacked down. He decided to take this up as a challenge, and with help from TCS Research and based on his own work, came up with a hand-held device that could precisely locate where the insect was inside the plant. Once the spot was identified, an organic neem-based chemical was injected into it in a gel or aerosol form. He went on to form Trebirth with Maitree Dedhia, who was also a part of the DISQ programme.

According to him, the core technology they use is the microwave Doppler radar system, which is used in car parking sensors to guide drivers to reverse or park vehicles. "The important aspect of the sensor is that it can penetrate wood," says Choudhary.

Farmers can now use the hand-held device to scan a plant and identify where the pest activity is happening. He adds that Trebirth has also devised an algorithm that recognises the movement patterns of the stem borer moth compared to, say, an ant in the vicinity, or a human hand.

Choudhary says the company is working on an X-ray-based detection device, too. The present device takes 30-60 seconds to scan a plant. Trebirth wants to bring this down to 2-5 seconds per plant so that large grape farms can be covered in a short time. Based in Nashik, Trebirth is testing and validating the product in farms in the region and hopes to launch it commercially later this year. Choudhary expects large grape farmers and farmer-producer organisations to be his customers. Once the device for grapes is launched, the company will look at other crops that face similar problems.

ABX3PV

Founders: Laxman Gouda, Aditya Sadhanala, Sushobhan Avasthi, Praveen C. Ramamurthy and Gangadhar Rao

Year: 2023

Big idea: To develop and produce perovskite solar cells as an alternative to silicon solar cells

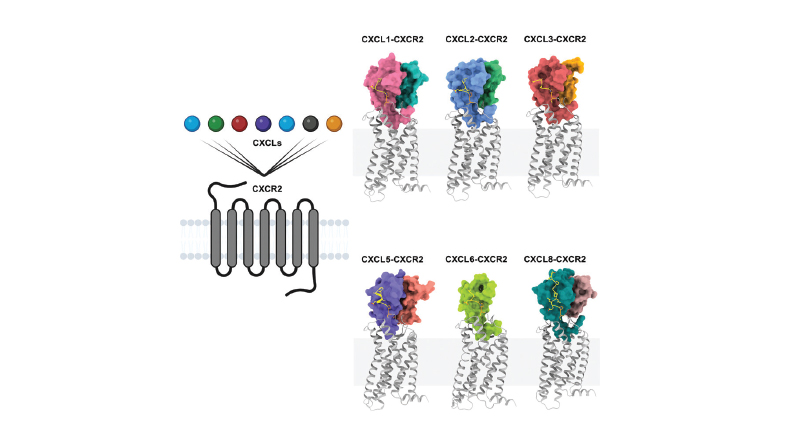

Ask Laxman Gouda about the significance of the name ABX3PV, and he explains that it refers to perovskite, a class of materials used to make solar cells. Perovskite earlier referred to the mineral calcium titanium oxide but the name is now used for an entire family of materials with the same crystal structure.

Gouda, who studied biotechnology and chemistry, joined the Indian Institute of Science (IISc) in Bengaluru and then went to Israel to obtain a PhD in solar cells. He returned to IISc and co-founded the start-up with three other IISc Professors — Aditya Sadhanala, Sushobhan Avasthi and Praveen C. Ramamurthy — and an industry expert, Gangadhar Rao.

Perovskite solar cells (PSCs) are being seen as an alternative to silicon solar cells, which are not just expensive but produced by only a handful of countries (The promise of cheaper solar power). Much of the silicon solar cells being used in India is imported. He adds that researchers across the world are working on PSCs, and a few companies are working to market it.

The company has a working prototype with which it will evaluate and validate the technology.

ABX3PV, Gouda says, will use a hybrid perovskite material that has shown promising results in the lab. One of the materials that the venture is working on is a composite of caesium iodide, formamidinium iodide/bromide and lead iodide. "It can reach 30-31% efficiency, compared with 26-27% for silicon solar cells," he says. The novel process is extremely challenging, he adds. "But we have the facilities and the expertise to meet these challenges." The company can now make 10cm x 10cm PSC modules and wants to produce 20cm x 30cm modules. In parallel, it is trying to build the equipment for mass-producing solar panels. ABX3PV, he adds, is willing to engage with large players in the solar power ecosystem, as well as the Defence Research and Development Organisation and the Indian Space Research Organisation, to test and validate its solar panels. PSCs can also be integrated with existing silicon solar cells (tandem solar cells), to improve the efficiency of solar panels. The company has a working prototype with which it will evaluate and validate the technology.

According to Gouda, PSC can be applied on glass, sheet and flexible material. The founders hope to start mass production by the year-end when they expect to have raised funds. Gouda says the company will only make solar cells, which it plans to supply to end-users such as solar power-generating companies.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH