The paper partition for batteries

-

- from Shaastra :: vol 03 issue 04 :: May 2024

This paper-and-ceramic separator makes lithium-ion batteries safer and more sustainable. It has wide applicability.

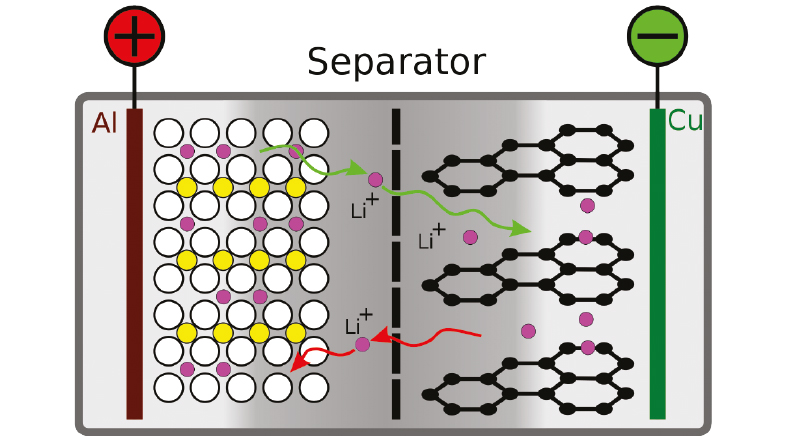

Researchers have developed a paper-based separator for lithium-ion (Li-ion) batteries that they call the 'Paperator'. Separators in Li-ion batteries perform the important task of creating a partition between the anode and cathode so that there are no short circuits. Current Li-ion batteries come fitted with plastic or polymer-based separators made of polypropylene or polyethylene. When battery temperature rises, the separators start softening. As the separators fail, the chances of anode and cathode coming in contact with each other increase and can result in a fire.

Unlike the polymer separators, the Paperator is made of cellulose paper that is impregnated with ceramics (aluminium oxide, barium titanate or zirconium dioxide). The ceramics enhance the structural integrity of the separator, impart flame-retardant properties and provide higher thermal stability. In laboratory tests, the Paperator was found to be stable at temperatures as high as 200°C.

While it is important for separators to prevent contact between anode and cathode, they should allow a free passage for movement of lithium ions through the electrolyte. For this, their electrolyte-uptake ability should be high. In conventional polymeric separators, electrolyte uptake has been a pain point. The Paperator shows a higher electrolyte-uptake ability, ranging from 175% to 350% based on the ceramic material used. It also shows a high-cycle life, performing well for up to 300 cell cycles. It displays more than 98% coulombic efficiency, the ratio of total charge extracted from a battery to the charge put into the battery over a cycle.

Unlike polymer separators, the Paperator is made of cellulose paper impregnated with ceramics.

Additionally, the separator has wide applicability. "It can be used for Na-ion, Li-ion and even super capacitors," says Mir Wasim Raja, Senior Scientist at the CSIR-Central Glass & Ceramic Research Institute (CSIR-CGCRI), Kolkata, and the study's lead researcher. "No company in the world is making such ceramic-based paper separators," he adds. The researchers published their findings in the Journal of Power Sources (bit.ly/paperator). They have also filed a patent for the Paperator and are collaborating with two commercial entities to take it from the lab to the market; the patent is still to be granted. Based on some primary calculations, it is expected to cost "nearly half" of current separators, says Raja.

The study has demonstrated a scalable approach for a safer and high Li-ion transfer capacity separator, says T.N. Narayanan, Associate Professor at the Tata Institute of Fundamental Research-Hyderabad. "Ceramics are safer and have synergistic roles in ion transport and hence this work opens up (a) plethora of opportunities in this research area."

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH