These scientists have shattered the glass ceiling

-

- from Shaastra :: vol 03 issue 06 :: Jul 2024

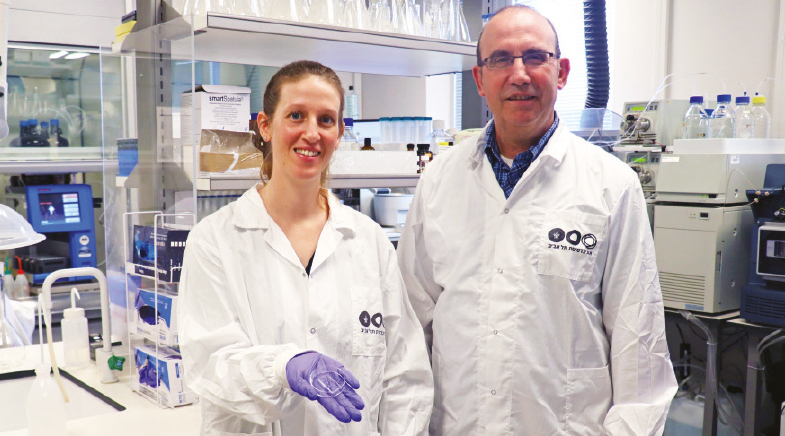

Scientists at Tel Aviv University have made self-healing, adhesive molecular glass out of a little piece of protein.

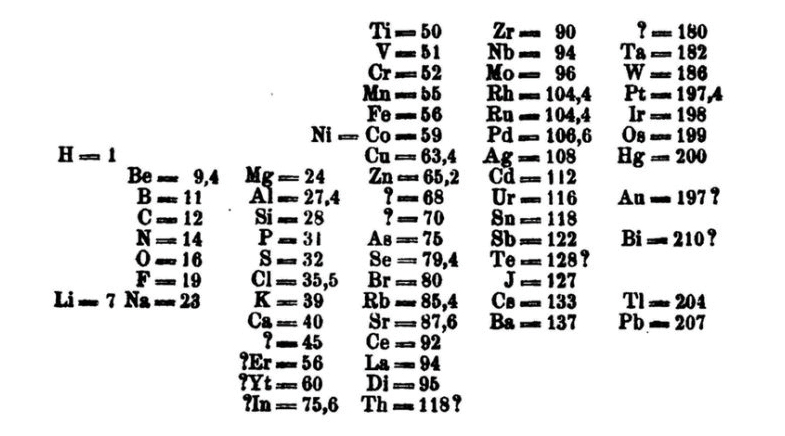

It all started with an accidental discovery at Tel Aviv University (TAU) in Israel three years ago. While working on tyrosine, a natural amino acid, a team led by scientist Ehud Gazit found that the biomolecule could take an amorphous molecular form, a prerequisite for glass formation. As their work continued, they found that a glass-like material could indeed be made from an organic compound as simple as a tripeptide, which consists of a linear chain of just three amino acids.

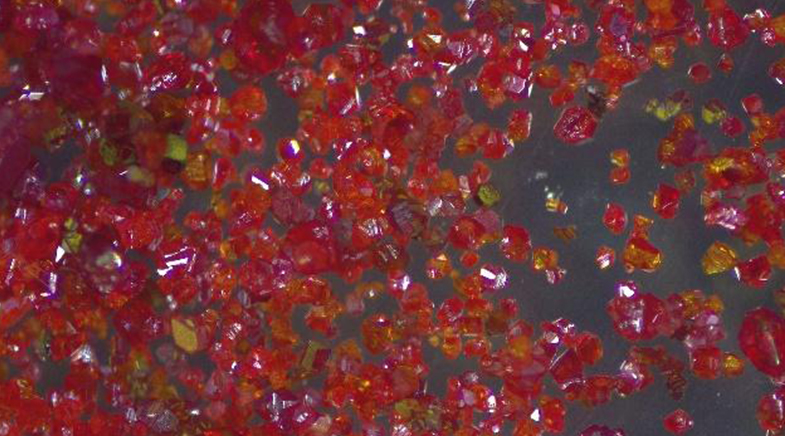

The work, recently published in Nature (bit.ly/Nature-Glass), is remarkable because it defies the peptide's natural propensity to make ordered crystalline structures. "This was quite unexpected," says Gal Finkelstein-Zuta, Gazit's doctoral student and one of the two lead authors of the study.

The material has properties that do not exist in any glass, Gazit notes. It can be produced at room temperature, is self-healing, and exhibits a strong adhesive property. It is transparent and has a natural tendency to form curved shapes.

BUILDING BLOCKS

Gazit has been working for long on peptides – shorter versions of proteins containing a small number of amino acids — as building blocks for new materials. Peptides make excellent chemical building blocks in nature, as they can self-assemble into biomolecules with unique structures. Hormones such as insulin and oxytocin are made of peptides, for instance. His team has been using peptides to make a range of bio-inspired products, such as nanospheres, nanotubes, and nanoscale hydrogels. Many products derived from such peptides are slowly entering the market.

After the initial breakthrough, further studies by the team at TAU's Department of Materials Science and Engineering — leading to the current paper — demonstrated that while peptides containing one, two or four tyrosine amino acids formed crystals, those with three tyrosine molecules, when stirred with water, formed a glass-like structure after the water evaporated. The water molecules were found to build bridges with peptide molecules, helping to stabilise the amorphous liquid-like organisation found in the tripeptide glass.

The glass is transparent, self-healing, exhibits a strong adhesive property, and has a natural tendency to form curved shapes.

"Our peptide glass is formed spontaneously, at room temperature, without the need for high heat or pressure. To our knowledge, a spontaneous formation of glass at room temperature from small organic molecules has not yet been reported," says Finkelstein-Zuta.

Glass is traditionally made with materials such as sand, soda ash, and limestone. Humankind has been making glass for almost 4,000 years; the earliest glass objects were reported from parts of Egypt and Mesopotamia. The products included luxury items such as beads and ornaments or objects of art. A few hundred years ago, glass started being used in bottles, jars, other such storage objects, crockery items, windows, and doors. Despite being heavy and brittle, it continued to be popular even after the advent of plastic, which cornered a large chunk of the packaging and storage market. According to the International Commission on Glass, 209 million tonnes of glass were produced in 2022. The global glass industry's revenues have been growing at 5.2% a year.

CARBON EMISSIONS

The process of making glass, however, is an energy-intensive one. The input materials need to be heated to very high temperatures and then cooled very rapidly, in a process called vitrification, to ensure an amorphous organisation and prevent the formation of an ordered structure, which is normally associated with crystals. Much of the glass used today — as in buildings, window panes, and containers — is made this way. According to the U.S. Environmental Protection Agency, the energy required to produce 1 tonne of virgin glass is about 6.49 million British Thermal Units, roughly equal to 1,900 units of electricity. Recycling glass is one-third cheaper than virgin production, but the process still needs an equivalent of nearly 1,265 kilowatt-hour units.

The process causes enormous ecological damage. The global glass production accounts for 95 million tonnes of carbon dioxide (bit.ly/Glass-Emission). Polymers, a viable substitute for glass in many applications such as containers, pose other kinds of environmental harm: most are non-degradable and remain in the soil and oceans for hundreds, if not thousands, of years.

The peptide glass made by the Israeli scientists may not replace silicate glass or polymeric glass in bulk usage. It can, however, emerge as a viable alternative to many high-end applications in optic and electro-optic fields.

The scientists also found the peptide glass had many exciting properties. With the right amount of water molecules, the glass remained ductile but developed cracks and became brittle when dehydrated. The cracks in the glass, however, disappeared when moisture was reintroduced, indicating a self-healing property. The peptide glass also exhibited a strong adhesive property, provided the surfaces were hydrophilic, that is, had an affinity for water. The scientists found that two microscope slides held together with the material could not be separated even by a 5-kg load.

UNIQUE PROPERTIES

The fact that the glass can form strong bonds with surfaces due to its adhesive properties may be particularly useful in applications requiring secure adhesion. Additionally, its self-healing capabilities allow it to repair cracks or damage autonomously when exposed to water, a feature not commonly found in traditional adhesives or other materials. This self-repair mechanism can prolong the lifespan of products and reduce the need for manual repairs or replacements.

The glue-like property of the peptide glass may help bond layers of different materials to make lenses, says Silvia Marchesan, a chemist specialising in nanotechnology at the University of Trieste in Italy, in a commentary in the same edition of Nature (bit.ly/Glass-Self-Healing). "Multi-layered lenses are highly sought after for high-performance technologies because each layer can provide a different function, such as scratch resistance and anti-fogging," she says.

The peptide glass is transparent across visible and infrared wavelengths of light and is found to have a refractive index close to that of commonly used optical glasses. Besides, the glass naturally tends to form curved shapes as the water in the solution evaporates during the manufacturing process. Exploiting this property, Gazit and colleagues have produced convex lenses of different curvatures, and thus of different focal lengths. Such lenses are made today through a lengthy process of grinding and polishing. With all these properties, the scientists hope, the peptide glass will have many potential applications in fields such as satellites, remote sensing, communications, and optics.

Scientists believe that peptide glass will have many potential applications in fields such as satellites, remote sensing, communications, and optics.

"This is a very important contribution as it now makes it possible to produce biodegradable glass materials," says Hosahudya N. Gopi, Professor at the Indian Institute of Science Education and Research Pune. Gopi was not connected with the study.

In a statement issued by TAU, Gazit describes it as a "very special glass". "This is the first time anyone has succeeded in creating molecular glass under simple conditions," he says. "But not less important than that are the properties of the glass we created... It is very strong and... very transparent — much more transparent than ordinary glass... The molecular glass we created is transparent deep into the infrared range... We got all this from a single peptide — one little piece of protein," Gazit says.

Researchers have been taking advantage of the low cost, robustness and chemical diversity of simple amino acid derivatives to find molecules that self-assemble into biodegradable materials with technological applications ranging from healthcare to energy harvesting (They pass the acid test). But these are still to hit the market.

Currently, making peptide glass on a large scale may not be economically viable as it is expensive to synthesise the peptides. But as seen with many commercially available peptide-based materials, they tend to become cost-effective, says Finkelstein-Zuta, citing the example of aspartame, an artificial sweetener derived from dipeptide.

Suryasarathi Bose, Professor of Materials Engineering at the Indian Institute of Science, Bengaluru, agrees. "Large-scale production (of the peptide glass) looks challenging at this moment, but you know how applications drive large-scale production (of new materials). Carbon nanotube is a classic example," he says.

The current work has showcased the potential of using simple organic compounds to create advanced glass materials with novel functionalities. It is certainly a 'glass-shattering moment' for the global glass industry.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH