The promise of biodegradable ‘aquaplastic’

-

- from Shaastra :: vol 01 edition 01 :: May - Jun 2021

AN ESTIMATED 335 million tons of plastic is produced annually the world over, causing potentially irreversible damage to the environment because plastic is largely non-biodegradable. Bioplastics are somewhat more eco-friendly, but they constitute less than 1% of the total plastic production.

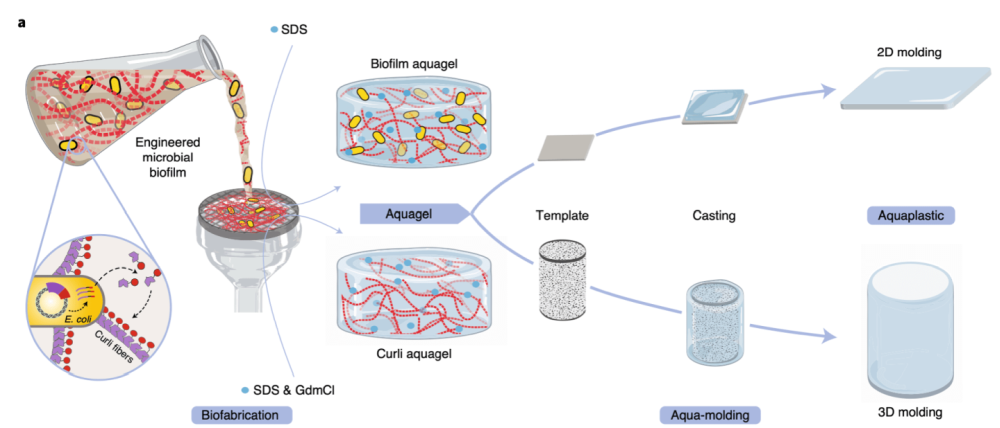

Now, scientists in the US have fashioned a new class of microbial biofilm-based biodegradable bioplastic processed with water. The researchers, some of whom have an Indian connection, have coaxed a genetically engineered common bacterium – E. coli – to produce long protein nanofibres that can be cast and dried to create a plastic with mechanical properties similar to those made from petrochemicals.

The new material is also capable of withstanding strong acids, bases and organic solvents.

More importantly, unlike conventional plastics, which require thermomoulding, hydrogels made of these protein nanofibres can be moulded, welded and healed by water, earning it the sobriquet ‘aquaplastic’. The scientists, led by Neel Joshi at Northeastern University in Boston, reported the findings, which are largely a proof of concept, in a paper published in Nature Chemical Biology journal.

“Our material combines several properties that are useful in the context of bioplastics,” said Joshi, the principal investigator for the study. “It is made from a biological system, it is biodegradable, and it can be customised for specific performance applications. There are few bioplastics that are both made from biology and biodegradable – only those based on starch or certain polyesters (for example, polyhydroxyalkanoates). None of the existing polymers can rival our protein fibers in terms of molecular customisability, which will be advantageous for achieving different performance characteristics,” Joshi said.

The work on aquaplastic, in fact, began earlier, when Joshi was with Wyss Institute for Biologically Inspired Engineering at Harvard University. He and his postdoctoral fellows – Anna Duraj-Thatte and Avinash Manjula-Basavanna – also first authors of the paper, observed that when these hydrogels produced by genetically engineered E.coli are cast and dried under ambient conditions, they can become plastic with mechanical properties comparable to those of conventional plastics.

Joshi, who grew up in the US but has roots in Mumbai, acknowledged, however that in its current state, aquaplastic will swell and rehydrate in water, making it inappropriate as a replacement for many types of plastic (for example, as water bottles). “This is a problem we are working on, trying to leverage the customisability of AquaPlastic to imbue it with water-resistant properties,” Joshi said. “There are some immediate applications that we are pursuing.

Some polymers (such as polyvinyl alcohol) are designed to be water-soluble. PVA forms the pouch that dishwasher detergent pods come it, for example. Although PVA is soluble, it is not very biodegradable. Aqua- Plastic could replace PVA with a biodegradable alternative,” he added.

Manjula-Basavanna, who did his PhD at the Jawaharlal Nehru Centre for Advanced Scientific Research, in Bengaluru, said the researchers are confident that AquaPlastic can find potential applications in primary packaging and protective coating.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH