Alga shows the way

-

- from Shaastra :: vol 04 issue 10 :: Nov 2025

Researchers are looking at ways to use microalgae as a carbon cleanser.

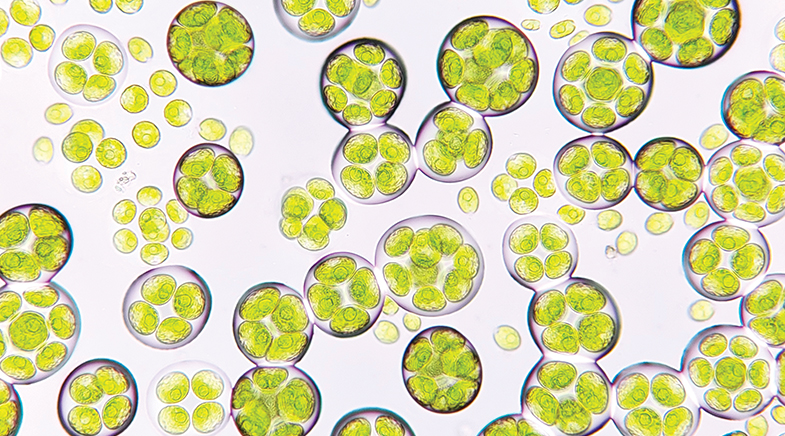

For single-celled organisms, microscopic algae or 'microalgae' have considerable clout in nature. Found across freshwater and marine ecosystems, these photosynthetic organisms provide oxygen. And because they lack leaves, stems and roots, they can fix carbon dioxide (CO2) 10-50 times faster than land plants. "They generate biomass pretty quickly," says microalgae researcher Prachi Nawkarkar. The carbon that is taken up by the cells is fixed in the form of carbohydrates, lipids and proteins in the algal biomass, she adds. The biomass can then be utilised directly as a fertiliser or to derive biofuel and other by-products, making microalgae a potential biological pathway for carbon capture and utilisation.

Utilising captured carbon is at the core of what Greengine Environmental Technologies does. The Kanpur-based climate tech start-up has developed a microalgae-based carbon capture and utilisation technology for industrial decarbonisation. "Microalgae will grow if you provide nutrients [and] carbon dioxide," says Founder Nitin Srivastava. To do that at scale for a specific purpose, however, requires engineering, he says. "It's not easy to cultivate microalgae at scale."

Microalgae have considerable clout in nature: they sequester carbon dioxide faster than land plants.

So, instead of using conventional artificial ponds or tubular reactors, Greengine has developed a novel bioreactor design. The bioreactor, the details of which are under wraps, uses 50% less water and energy than conventional systems, Srivastava claims. The harvesting of algal biomass for utilisation will also be less energy-consuming. The company is about to launch its compact bioreactor unit. The unit can use flue gas, i.e., industrial exhaust (after its temperature has been reduced), as a source of CO2 for algae cultivation.

While biological carbon capture is naturally slow, the advantage is that it results in biomass, and not CO2. "That biomass is valuable in terms of lipid, proteins, carbohydrates," Srivastava says. The company is exploring applications for it. "For us to close the loop [is] very important," he says. "I can't just put a reactor and say the biomass has been generated and then let you keep the biomass unutilised because then the carbon will get remitted." It is working to generate biogas (methane) and biomaterials from algal biomass.

"When I say materials, I'm more focused on using these as bio-fillers in conventional polymers and rubbers," he explains. Made from renewable sources, bio-fillers enhance the properties of composite polymer materials. Making bio-fillers from algae is more climate-forward than making biopolymers. "We have extracted polymers out of microalgae biomass as well," Srivastava says. But the energy requirements were found to be too high.

MULTITASKING MICROALGAE

In southern India, Karthika Gopi is working on similar lines, while using ambient air — both indoor and outdoor — to capture CO2 and provide clean air in return. Microalgae are natural air purifiers, says Gopi. Her start-up, Carbelim, is making microalgae-based air purifiers that can capture carbon along with air pollutants and produce oxygen.

"Whatever we have in the traditional market is just a mechanical filter," says Gopi, Founder and Chief Executive Officer of Carbelim. While the usual air purifiers filter out particulate matter and volatile organic compounds from the air, they do not produce oxygen. "Here we can unleash the power of microalgae to convert it into fresh oxygen and also capture the carbon," she says. The units come with built-in Internet of Things (IoT) sensors for monitoring air quality index data in real time.

The indoor air purifiers, meant for use in homes, malls and offices, will be equipped with artificial lighting and ultraviolet sterilisation to neutralise the odour of algae, Gopi says. Carbelim is also developing façades for building exteriors and outdoor air-purifying towers that will use natural light. Annually, the living façade can capture about 52 kg of CO2 and release 25,000 litres of oxygen per square metre of the panel, according to Gopi. The green façade will reduce the building's overall carbon footprint, she says.

The towers for outdoor installation have the air-purifying impact of 15 trees each, Carbelim claims. It formulates separate consortia of microalgae for these indoor and outdoor applications to ensure their adaptability to varying light intensities, temperatures, and humidity levels.

Like Greengine, Carbelim wants to utilise the biomass generated. It is exploring value-added products such as Omega-3 oil and vegan protein, for which Carbelim is collaborating with research institutes in Coimbatore, Tamil Nadu, where its R&D unit is located.

Algae may help reduce air pollution, but they still need water to grow. Typically, microalgae require 2.4-6.8 m3 of water per kg of biomass produced. Their water requirements are even higher than those of rice (bit.ly/microalgae-CO2). Start-ups and research labs are therefore turning to wastewater for their cultivation.

WASTE NOT

Mumbai-based AgroMorph Technosolutions began as an algae-based product business in 2019. But due to the high freshwater requirements for algal cultivation, the company pivoted to wastewater two years later. "We didn't want to use fresh water," says Founding Director Akanksha Agarwal (also see: Macro issues, micro solutions).

Agarwal points out that algae, being photosynthetic organisms, will sequester carbon no matter where they grow, be it in domestic or industrial wastewater. "What we have added to that aspect is the component of putting in flue gas as an additive to our treatment systems."

Depending on the industry, CO2 concentration in flue gas can reach 30%. "Obviously, 100% of it will not be taken up by algae because there is a natural limitation to how much algae can pick up." For every tonne of algae grown, AgroMorph captures 1.72 tonnes of CO2. "The theoretical value is about 1.8," says Agarwal. AgroMorph uses sensors to measure how much CO2 is going in and out of its photobioreactors. "If there is excess and insoluble CO2 left in the air, it will escape."

AgroMorph cultivates green microalgae, including Chlorella and Chlorococcum, and species of red microalgae for wastewater remediation and carbon capture. While using wastewater for algae cultivation eliminates the need for freshwater, it limits applications. "When we're working with domestic wastewater, the biomass is taken only for biofertiliser because of the perception that it is growing from waste," says Agarwal. That said, wastewater from the food-and-beverage industry is essentially organic matter, and algae cultivated in it can be harvested for animal feed.

Since biomass enables utilisation, researchers are keen to enhance algal productivity to lower the costs of derivatives such as biofuels and biochar. Nawkarkar, who is a researcher with the International Centre for Genetic Engineering and Biotechnology in New Delhi, is genetically altering algae to achieve the dual goals of increased productivity and carbon sequestration.

While algae have a better CO2-sequestering capacity than plants, as aquatic organisms, they have to obtain CO2 from water, Nawkarkar explains. "The only thing is that carbon dioxide is not that abundant in water. Obviously, it's a gas. So, it is more readily available to terrestrial plants than... algae."

Algae have therefore evolved a CO2-concentrating mechanism to overcome this. "They have devised a system which can just take up CO2 from the aqueous environment, and through proper steps inside the cell, it reaches RuBisCO, which is the main machinery that fixes CO2." Even then, algae can sequester a limited amount of CO2. "If you want the algae to sequester more CO2, for example 10%, 15% which is found in your exhaust gases, you need to tweak that system."

That's what Nawkarkar and colleagues have done with the marine microalgal strain Parachlorella kessleri-I. They genetically engineered the strain to overexpress two proteins (from green microalga Chlamydomonas reinhardtii) so that carbon was sequestered continuously to produce more biomass. They cultivated the genetically modified and wild-type strains of P. kessleri-I first at a small scale of 2 litres, and then at 20 and 100 litres (bit.ly/GM-algae).

In a 100-litre photobioreactor using wastewater, the genetically modified strain's biomass productivity was two times that of the wild-type strain. The activity of certain enzymes also increased, indicating more carbon sequestration, explains Nawkarkar.

"The beauty of this organism is that it's marine," she says. It doesn't rely on fresh water for its growth. On top of that, it can survive in urban wastewater. "It will not be a burden on any kind of natural resources."

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH