Enzymes and energy

-

- from Shaastra :: vol 04 issue 01 :: Feb 2025

Researchers are looking at cheaper power, better drug delivery, and breaking down plastic on an industrial scale.

APRATIMA BIOSOLUTIONS

Founder: Kavyashree Manjunath

Year: 2022

Big idea: To develop an enzyme that can break down PET waste on an industrial scale

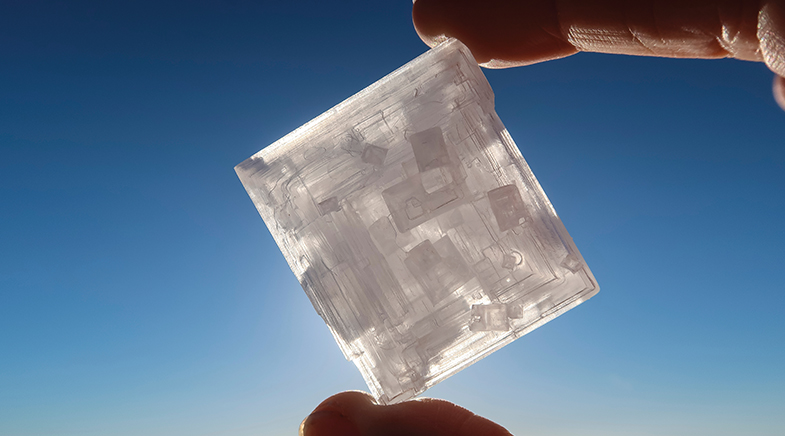

Surrounded by mounds of plastic in her lab, Kavyashree Manjunath realised she had to do something to tackle the growing problem of plastic waste. After completing her PhD from the Indian Institute of Science – in protein structural biology using X-ray crystallography – she worked as a research scientist in a drug discovery laboratory, where she was exposed to the humongous amounts of plastics required during high-throughput screening experiments. "If in a single lab, we are generating so much plastic waste, just imagine the amount of plastic waste generated across the country or globally," she says.

Manjunath studied pollution caused by plastic waste and looked at technologies that could mitigate its harmful effects. She found that polyethylene terephthalate (PET) bottles could be theoretically recycled six or seven times using mechanical recycling, but the output quality deteriorated after each round. "The problem is so serious (but) it is not being addressed effectively. I was looking for a biological solution, given my area of expertise," she says. So, she turned to enzymes.

All living organisms produce varieties of enzymes for carrying out particular biological functions. Enzymes, she explains, are biological catalysts that speed up specific chemical reactions and break down chemical bonds. Some enzymes have evolved the ability to break down plastics like PET.

Manjunath decided to work on engineering enzymes to enable a quick breakdown of plastics. She wrote a research proposal for academic positions. She also applied for the Biotechnology Ignition Grant (BIG) of the Biotechnology Industry Research Assistance Council, which supported her project with a grant. During the grant period, she decided to form a venture — and Apratima Biosolutions was born. Apratima means unique, and the name was apt as Manjunath wanted to use her expertise in protein engineering to find a novel solution to PET waste.

The company has developed a machine learning pipeline that will help her identify the specific regions of an enzyme that need to be mutated to improve its functioning. "My goal was to develop an enzyme that could be used to break down PET waste at an industrial scale. When the PET waste is broken down, the product that comes out can be purified and used as a raw material," she says.

Apratima Biosolutions has readied a proof-of-concept for a working enzyme that breaks down PET waste. The company has filed a patent for the technology. Manjunath says it is now working towards developing pilot studies to prove that the enzyme works at an industrial scale, after which it will commercially launch the product.

ANUBAL FUSION

Founder: Pravin Kini

Year: 2024

Big idea: To develop nuclear fusion technology and generate electricity

Lasers fascinate Pravin Kini. The serial deep tech entrepreneur with a medical background has set up a venture to develop nuclear fusion technology using intense lasers to generate electricity.

Laser technology figured in each of his earlier ventures: in his quantum cryptography company, for instance, it was used to make hack-proof key distribution system. At Anubal Fusion — Anubal is a portmanteau of two words denoting nuclear and energy — he seeks to use lasers to generate electricity.

Nuclear fusion technology has been gathering eyeballs for a while. However, global research activities on this technology have increased only in the last decade or so, with the U.S., China, and the European Union investing in the area. Unlike nuclear fission, which splits a large atom (typically uranium) into smaller atoms releasing high energy in the form of heat, fusion combines two small atoms into a larger one, releasing energy several times higher than that generated in fission.

According to Kini, two techniques are employed to generate fusion energy: Magnetic Confinement Fusion (MCF), the traditional way, and Inertial Confinement Fusion (ICF), which has demonstrated more encouraging results than MCF. The net positive energy, or q, of MCF has never been more than 1. However, because of developments at the National Ignition Facility, a laser-based fusion research centre in California, the q factor for ICF has constantly been increasing. It is now close to 2, proving that the technology is cost-effective and can be scaled.

He says several technological advancements are helping in the development of laser fusion. High-performance supercomputing, for instance, has made it possible for researchers to study fusion better. Further, petawatt lasers — petawatt is a unit of power equal to 1015 watts — will help in fusion technology.

A petawatt laser is being set up at the Tata Institute of Fundamental Research, Hyderabad. Anubal Fusion, he says, has tied up with it to conduct laser experiments. Till the facility becomes operational, the company, incorporated in Delhi-NCR, will conduct computational studies. In the first phase, Anubal will do simulations as these account for nearly 80% of the R&D work in fusion energy. Following the simulations, experiments on the petawatt laser will be conducted. "The third stage — of commercial production — should likely happen in 2029," Kini says. He adds that the capital and operational expenditures for a fusion energy plant will be considerably lower than those needed in a nuclear fission plant. The cost of producing electricity will be significantly lower, too, he adds. The results of the experiments will determine the next steps.

GENICA BIOSCIENCES

Founder: Roopa Jones Ganji

Year: 2021

Big idea: A biotechnology company developing animal-free enzymes and diagnostic kits

It was while doing her PhD in Biochemistry at the CSIR–Indian Institute of Chemical Technology that Roopa Jones Ganji thought of developing some of the enzymes she used in her research work instead of buying them. "It occurred to me: why not make our own enzymes instead of buying or importing them?" she says. She worked on this, and after submitting her thesis, decided to start a venture to produce molecular biology and industrial enzymes, and molecular diagnostic kits for infectious diseases.

The start-up, Genica Biosciences, develops novel enzymes and therapeutics that are not available in the market, have to be imported or are too expensive. Besides, most of the products used in pharmaceutical products or vaccines are extracted from animal tissues. Ganji wanted to come up with animal-free alternatives.

One of the proteins she chose was hyaluronidase, an enzyme that has long been used to increase the absorption of drugs into tissues. She says that Genica, which mostly depends on grants, specialises in recombinant hyaluronidase production, delivering enzymes of high purity for various applications. The enzymes can efficiently degrade hyaluronic acid in pharmaceutical, medical, and cosmetic formulations, thus facilitating enhanced drug delivery and tissue permeability. This product is ready but must undergo clinical trials before being commercially launched. Genica Biosciences, she says, will collaborate with partners for the trials. The product may take about five years to hit the market after the trials.

Genica Biosciences is developing a recombinant endotoxin kit, which is likely to be ready in about six months after it is tested and approved.

The Hyderabad-based company is also working on endotoxin kits for molecular biology tests. Ganji says traditional endotoxin testing methods are time-consuming and involve practices that may not be sustainable. For instance, some of these testing methods use blood from a particular crab species, which is why it is feared that the species may become extinct. With a greater emphasis in the pharmaceutical industry on sustainability and on the three 'R's — replacement, reduction and refinement — of animal tests, researchers are focusing on cutting down on the use of animal extracts. The use of recombinant endotoxin kits is being encouraged in this context. Genica Biosciences is developing a recombinant endotoxin kit, which will likely be ready in about six months after it is tested, validated, and approved by regulatory authorities. Ganji adds that Genica is also working on developing recombinant enzymes free of animal extracts for use in the lab-grown meat industry.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH