These start-ups are speedy and smooth

-

- from Shaastra :: vol 03 issue 07 :: Aug 2024

Start-ups are working on high-quality silk, indigenous multi-fuel jets, and rapid, point-of-care blood test results.

DG Propulsion

Founders: Prateek Dhawan and Chirag Gupta

Year: 2019

Big idea: To develop a multi-fuel jet engine

Prateek Dhawan was passionate about jet engines. He started tinkering seriously with rotors and compressors as a third-year student of Mechanical Engineering at the National Institute of Technology Jalandhar. He posted videos of his work on the Internet and met like-minded people online from across the world.

The videos caught the attention of former Defence personnel in Delhi who were interested in indigenously developing jet engines. Dhawan met some of them before he left for his Master's in Mechanical Engineering in the U.S. During his Master's programme, Dhawan honed his interest, working on various aspects of designing a small jet engine. In 2019, he set up DG Propulsion with Chirag Gupta, a former Indian Navy officer.

Dhawan and Gupta were convinced of the need for an India-made jet engine as more use cases were coming up, especially with the widespread use of drones. "The obvious thing for us was to start small," says Dhawan.

Small jet engines, he adds, have a thrust of up to 300-350 kg. Punjab-based DG Propulsion decided to focus on engines in the very small category — with a thrust of 40-60 kg. A 100-kg thrust engine is also under development, he adds. These engines, he says, are suitable for uncrewed applications as they do not have to go through the same testing, certification, and scrutiny as manned applications.

According to him, DG Propulsion has designed, developed, and tested a 40-kg thrust engine. The biggest challenge it faced in developing the engines was that the rotors would fail as the engine revved up to higher revolutions. After several rounds of testing and analysis, he found that as the engines reached a critical speed, the vibrations increased multiple times, putting more load on the bearings — which then collapsed. "We were destroying bearings. That is when I found out that this had to do with rotor dynamics," says Dhawan.

He got in touch with a professor from the University of Virginia who had formed a company that made software for rotor dynamics analysis. The professor allowed him to use the software for a limited period, and Dhawan was able to identify and rectify the problem. "On January 1, 2021, we went past that critical speed," says Dhawan. DG Propulsion, he says, has developed multi-fuel engines and hopes to start selling them shortly, initially to power drones.

SeriGreen

Founders: Venkatesh D. and Vennila M.

Year: 2023

Big idea: An agri-tech venture to help sericulture farmers improve yield and quality

Venkatesh D. belonged to a sericulture family in Sathyamangalam, Tamil Nadu, and wanted to help silk farmers improve their productivity and yield. So, after graduating in Electrical and Electronics Engineering and a stint in a private factory, he started a venture for sericulture farmers. He co-founded SeriGreen Technologies with Vennila Murugesan, a computer science engineer. Vennila, who is from a silk sari-weaving family, knew the problems weavers faced in obtaining quality silk.

In China — the largest producer of silk — silkworms are bred only for four months a year, a practice that leads to superior silk. In India, on the other hand, silkworms are bred throughout the year, even though climatic conditions are not ideal for this. Farmers in India have been trying to genetically modify silkworms to enable them to grow in adverse climates. But when the silkworm becomes more tolerant to the environment, the quality of silk suffers.

The ideal temperature for breeding silkworms is 24-27°Celsius, Venkatesh says. However, the average temperature is higher in most of India's silkworm-growing regions, especially Tamil Nadu. High humidity, which can lead to diseases, is another problem. Different humidity levels are required at each stage of a silkworm's life cycle —ranging from 65% to 85-90%. The most crucial phase is the fourth stage of its life when the larva's food intake and growth peak. At this stage, the temperature should be 28°C and humidity, 65%.

Venkatesh says that SeriGreen has a solution to both problems. "It is easy to control temperature or humidity, but to control both is extremely difficult," he points out.

Incubated at the Pravartak Technologies Foundation at the Indian Institute of Technology Madras, SeriGreen is working on an IoT (Internet of Things) prototype that will use an air-cooled chiller, where water will be used instead of a refrigerant. It will continuously monitor the humidity. The company is building an experimental shed with the IoT device. The production, he hopes, will begin shortly. Sericulture farmers will be SeriGreen's customers.

Canary Biosensors

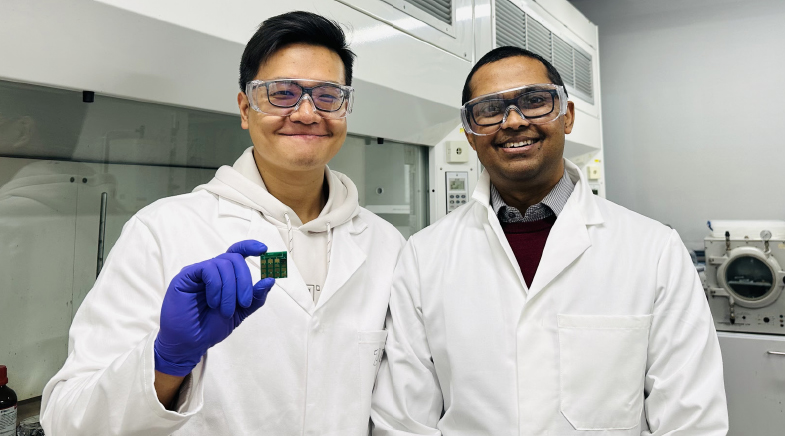

Founders: Kaushik Suresh and Amar Vignesh

Year: 2020

Big idea: To build point-of-care biosensors using electrochemical technology

When he was in his second year of college, Kaushik Suresh had to identify a problem and generate ideas to solve it as part of his coursework. He zeroed in on kidney health. The idea stayed with him and led the 24-year-old engineer to co-found a venture called Canary Biosensors with Amar Vignesh, who, like Kaushik, had graduated in Electronics and Communications Engineering from the Indian Institute of Information Technology, Design and Manufacturing, Kancheepuram.

Kaushik consulted hospital clinicians and doctors to understand what could be done to help those with kidney ailments. He soon realised that the average turnaround time in hospitals for testing creatinine in blood was 90 minutes. He felt a critical diagnostic report such as this should take less time. So, the founders of Canary Biosensors worked on an alternative, time-saving method.

Kaushik says the idea was to build a point-of-care test for creatinine and other markers required in hospitals. He says they initially thought of designing a home-testing system but decided to focus on hospitals and point-of-care testing instead. This meant that the test had to be conducted by the patient's side and the result had to be made available to the doctors within a few minutes. As most machines in use now are bulky and difficult to carry, Canary sought to design and build a device that was smaller and easier to handle.

The team also realised that electrochemical sensing was the best option as the tests could be done with a strip and electronic circuits, and no bulky instrumentation would be needed. It set about building an electrochemical sensor similar to a glucometer, used for testing blood sugar.

The idea was to build a point-of-care test for creatinine and other markers required in hospitals.

Kaushik adds that they started building a platform so that the device could be used for other, time-critical tests in hospitals in the future. Canary Biosensors is building an enzymatic sensor for serum creatinine, one of the vital markers for kidney health. It also wants to build a marker for cystatin C, which is considered an even more sensitive indicator of kidney health than creatinine. Initially, he says, they chose a platform called molecularly imprinted polymers. After working on this for nearly 18 months, they decided to go in for enzymatic sensors, because they wanted the technology to be simple and one that could be contract manufactured.

Canary Biosensors came up with a proof of concept within three months and has started testing with serum. "We have very good precision. Our range is in the clinically relevant range," Kaushik says. This device will provide results within two minutes and is a second-generation redox-mediated sensing system. Apart from the readings, Canary will also provide analyses. The company's customers will be hospitals.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH