How 3D printing offers the additive advantage

-

- from Shaastra :: vol 03 issue 04 :: May 2024

It is reshaping manufacturing and finding wider use.

When the first commercial 3D printers hit the market in the 1980s, they created much excitement in the world of business. 3D printing, or additive manufacturing technology, promised companies a way to make better, cheaper and unique products faster, while making maintenance easier. Components could be printed on demand. Since then, the range of industries that use 3D printing has widened. In 2021, Tvasta Manufacturing, a start-up founded by IIT Madras alumni, 3D-printed an entire house, the first in India (The great makeover). In Ukraine, where drones have played an important role in the country's war with Russia, an army of volunteers uses 3D-printing technology to convert commercial drones into military drones. Across the world, in medicine, it is used to create personalised prosthetics, implants, and surgical guides (Shape of things to come).

THE DRIVERS

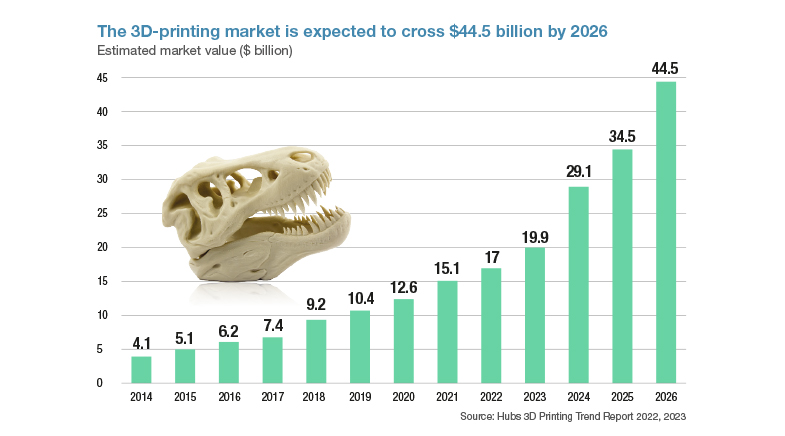

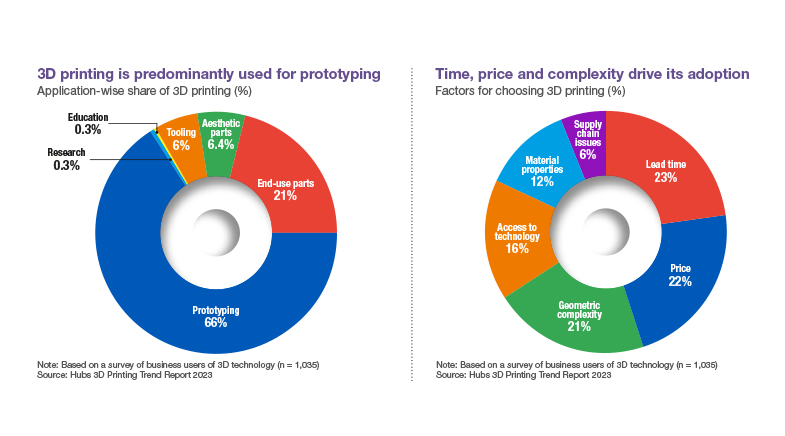

The 3D-printing market, including printing systems, software, materials and services, is expected to cross $44 billion by 2026, up seven times from 2016, according to Hubs, a part of Protolabs, a digital manufacturing firm. Currently, it’s used predominantly for prototyping, as it allows engineers to quickly iterate and test design. The technology is also used to make components.

While conventional manufacturing remains the best option for mass manufacturing, 3D printing offers other advantages for these specific use cases, including shorter lead time, lower costs for customised products and, most importantly, flexibility to make geometrically complex products, offering designers more freedom.

THE SCIENCE

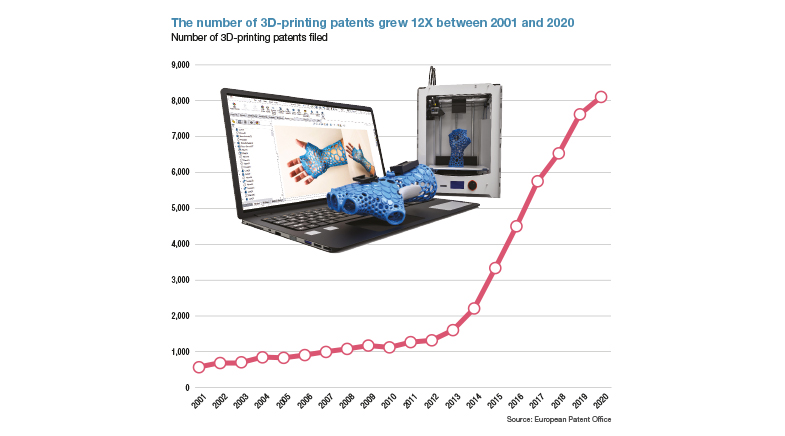

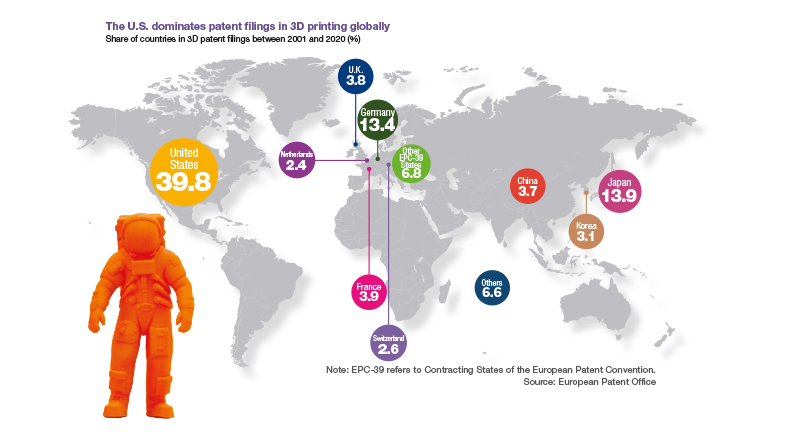

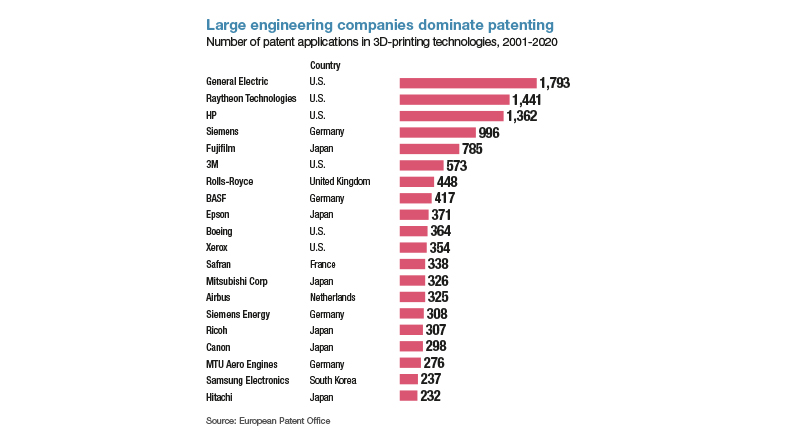

These benefits are a result of innovation in the field over the years. According to the European Patent Office (EPO), over 50,000 IPFs (international patent families) for 3D-printing technologies have been filed globally since 2001. These have resulted in improvements in hardware, software, materials and services, all of which have to work together. The U.S. and Europe account for over two-thirds of all the patents filed in this field since 2001, with the U.S. leading with a 39.8% share. Japan has a 14% share.

Some recent developments, in artificial intelligence (AI), robotics and the Internet of Things, are expected to complement 3D printing. Last year, for example, researchers at the Massachusetts Institute of Technology launched a generative AI-driven tool that allows users to add custom-designed elements to 3D models. China, which leads the world in the number of AI patents filed in recent years, has a 3.7% share in 3D printing.

THE CAPITAL

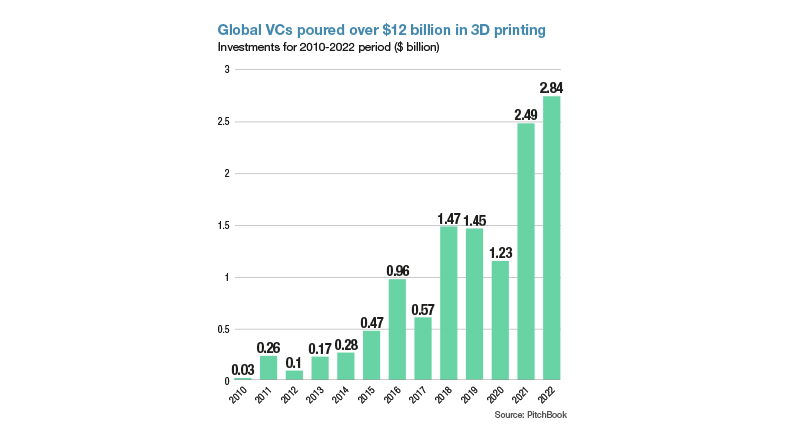

The dominance of the U.S., Europe and Japan is also reflected in the list of top 20 companies with the most patents in this field. Of the 20, six are based in the U.S., seven in Europe, six in Japan, and one in South Korea. "Although the list of top companies is dominated by large engineering companies in a range of sectors, the additive manufacturing innovation ecosystem consists of several specialised 3D printing companies and a vibrant start-up scene," EPO said. These start-ups are also attracting growing venture-capital interest, as they see demand for 3D printing growing in industries such as aerospace. This technology is best suited to make critical, complex components. Start-ups are also exploring innovative areas, such as food.

THE METHOD

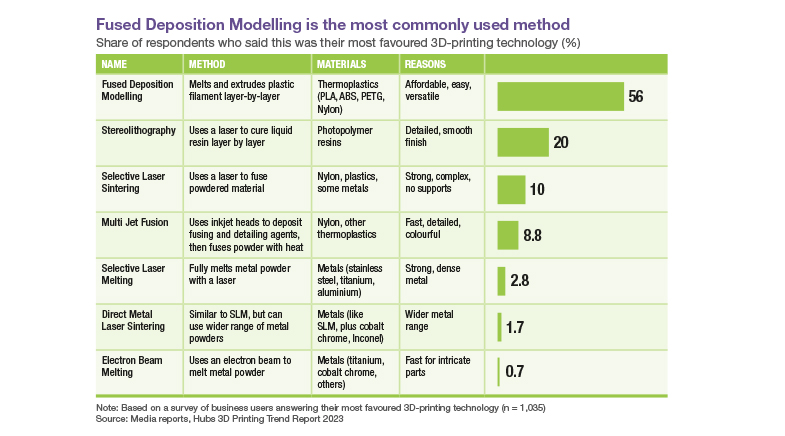

Already, 3D-printing technologies are widely used for their ability to produce complex geometries, offer a wide range of materials, and provide relatively fast turnaround times.

The future looks promising with technologies such as AI-assisted 3D printing and 4D printing. AI will help make 3D printing faster and create higher quality objects and improve how 3D-printed objects are designed and manufactured. Similarly, 4D printing uses special materials that can change shape in response to things like heat, light, or moisture. It has potential in healthcare, aerospace engineering, and fashion by allowing the creation of objects that can self-assemble or adapt to their environment.

See also:

The soft robo-touch

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH