Seaweed solutions

-

- from Shaastra :: vol 04 issue 08 :: Sep 2025

Seaweed is ready to sway the sustainable industry. But will it stay afloat or drown in a sea of expectations?

Wimbledon was different this summer. No, it wasn't the surface: the matches were still held on natural grass courts, as is tradition. Celebrities filled the Royal Box, as usual. What changed was how strawberries were served at the tennis championships in London. The iconic strawberries-and-cream came with spoons made not of plastic, but seaweed.

Last year, another shift had happened. The takeaway boxes for the Wimbledon strawberries were seaweed-coated to replace the plastic that typically lines food containers. The start-up producing these compostable seaweed-based packaging materials, Notpla (for not-plastic), has replaced 21.5 million single-use plastic items – and counting – at events across Europe.

Seaweed can replace anything, says Vincent Doumeizel, author of The Seaweed Revolution and Senior Advisor to the United Nations Global Compact. "It's really a multifaceted resource that can do a lot of different things." It can replace cotton, which is unsustainable due to its high water and pesticide use, he adds. Seaweed can cut fertiliser use. Efforts to make biofuels from seaweed are revving up, too.

What about seaweed makes it the go-to solution for our planetary problems? And can it compete with the fossil fuel industry? But first, what is seaweed?

HOLDING ON

'Seaweed' is the umbrella term for marine algae that are multicellular and macroscopic. Though macroalgae are not plants, they are often referred to as 'marine plants' because they photosynthesise and are partly responsible for the 70% of the oxygen that comes from the ocean.

Seaweeds don't need fertilisers, freshwater or fertile land to grow, which makes them an attractive resource.

Seaweed is a wide group from ecological, genetic and biodiversity perspectives, says Doumeizel. "This is the oldest complex organism on the planet." A billion years old, seaweed is the foundation of life on Earth, he adds. Seaweeds are broadly classified into three groups — red, green and brown. A green seaweed is closer to a tomato tree, strawberry or baobab than it is to a red seaweed, says Doumeizel. That's because about half a billion years ago, the green seaweeds moved to freshwater and evolved into the gamut of plants on land. The brown seaweeds, on the other hand, evolved around 450 million years ago. Brown seaweeds, such as the giant kelp, are the largest of seaweeds.

Seaweeds have no flowers or roots, and they attach to rocks or the seafloor with a structure called holdfast. As they need light to photosynthesise, they usually thrive in shallow coastal waters, both tropical and temperate. They grow very fast and capture a lot of carbon, says Doumeizel. "Some seaweeds can grow up to 40 cm a day to reach 60 m high." Unlike terrestrial plants, seaweeds don't need fertilisers, freshwater or fertile land to grow, making them an attractive resource for an assortment of applications — from food to fuels.

AS SUSTAINABLE FUEL

"India imports more than 85% of its crude oil," says Sri Sailaja Nori, Co-founder and Chief Scientific Officer of Sea6 Energy in Bengaluru. Sea6 was founded in 2010 with the aim to create a sustainable alternative. To meet India's annual crude oil requirement of 250-300 million tonnes, over a billion tonnes of biomass will be needed, Sailaja reckons. That is almost the entire agricultural productivity of our country, she says. "And that kind of scale cannot be achieved by growing more on land." The company sees huge possibilities in the ocean farming of seaweed (From seaweed to fuel). "This is probably the only feedstock that can scale and... actually be renewable," Sailaja believes.

Currently, biofuels, including biodiesel and bioethanol, account for about 4% of the transportation fuel globally. Biofuels are typically made from sugars and starches present in crops such as corn or from lignocellulose in grass and agricultural residues. Seaweed biomass contains carbohydrates such as alginates and cellulose. New biotechnology was needed to make this biofuel a reality, says Sailaja. That involved studying the seaweed's chemical composition and finding new enzymes for its biological conversion. But the limited knowledge available in this field made the company pivot to a thermochemical approach.

Using hydrothermal liquefaction, it has demonstrated the proof of concept for seaweed-derived biofuel. The method uses high temperature and pressure to convert feedstock into crude oil. It is a direct approach rather than trying to break down the seaweed into sugars and then fermenting them into ethanol, Sailaja explains. In 2024, Sea6 signed an agreement with Hindustan Petroleum Corporation Limited, an oil and gas giant, to develop industrial applications for its bio-crude oil, such as sustainable aviation fuel and chemicals. It is working with another company to scale up the production as well.

In parallel, Sea6 has been developing seaweed-based agricultural products for boosting plant growth and immunity, which it sells in 25 countries. It is also making biomaterials to replace single-use plastics and commercialising its food ingredients.

"We have developed a novel process which is low on carbon and energy footprint for making hydrocolloids from seaweeds, like carrageenans," Sailaja says. Carrageenans, which are extracted from red seaweeds, are used across the food-and-beverage industry. Applications include making ice creams and clarifying beer. Since seaweed is rich in potassium and low in sodium, it could "become a huge deal for reducing sodium intake" in foods, Sailaja foresees.

Sea6 is operating a mechanised farm in Indonesia to scale up the production and bring down the cost of seaweed for these varied applications.

FROM OCEAN FARMS TO TERRESTRIAL

The Global Seaweed New and Emerging Markets Report 2023 by the World Bank highlights 10 seaweed markets that have the "potential to grow by an additional USD 11.8 billion by 2030" (bit.ly/seaweed-2023). Going beyond the established markets for products like agar, carrageenan and aquaculture feed, it looks at new seaweed applications such as biostimulants, bioplastics, fabrics, nutraceuticals, construction and methane additives. The market for seaweed-based biostimulants, the report says, is projected to reach $1.8 billion in 2030.

"Biostimulants' key role in agriculture is to increase nutrient-use efficiency," says Tanmaye Seth, Chief Executive Officer of AquAgri Processing Pvt Ltd, New Delhi. "They help the plant take up more nutrition by positively impacting the metabolic functions." The functions can be growth, respiration or reproduction. In doing so, biostimulants help reduce fertiliser application by 25%, Seth says. On top of that, he adds, biostimulants help plants combat abiotic stress in the form of heat, drought, excess water, salinity and frost.

AquAgri makes biostimulants using a combination of three seaweeds: Kappaphycus, Gracilaria and Sargassum. While Kappaphycus, a red alga, is cultivated, the other two are collected from the Indian coast. "Right now, the entire cultivation in India is based on a single species," says Seth. The species, Kappaphycus alvarezii, is not native and was introduced to Indian waters.

To cultivate the seaweed, AquAgri works with seaweed farmers in the coastal districts of Rameshwaram, Tuticorin and Pudukkottai in Tamil Nadu. But due to rising sea temperatures, the productivity has almost halved, according to Seth.

SINK OR SWIM

Since the availability of seaweed can be a limiting factor in the seaweed value chain, some seaweed businesses are focusing on species that are abundant in nature — and harmful to the economy and environment in excess. Take Sargassum, a brown seaweed, for instance.

When the seaweed dies, it either sinks to the seafloor, sequestering carbon for thousands of years, or washes up on shores. Unlike most seaweeds which hold on to a substrate, two Sargassum species, S. natans and S. fluitans, are freely floating and form large mats on the ocean surface.

Sargassum is a huge problem in the Caribbean and West Africa, with lots of it stranding on the beach, says Franziska Elmer. Millions of tonnes wash up on Caribbean shores every year, impacting tourism and harming local fisheries. When it rots in the water, Sargassum sucks out oxygen, killing fish and seagrass beds. When it decomposes on land, either on the beach or in a landfill, it releases hydrogen sulphide and methane. "It smells really bad," says Elmer.

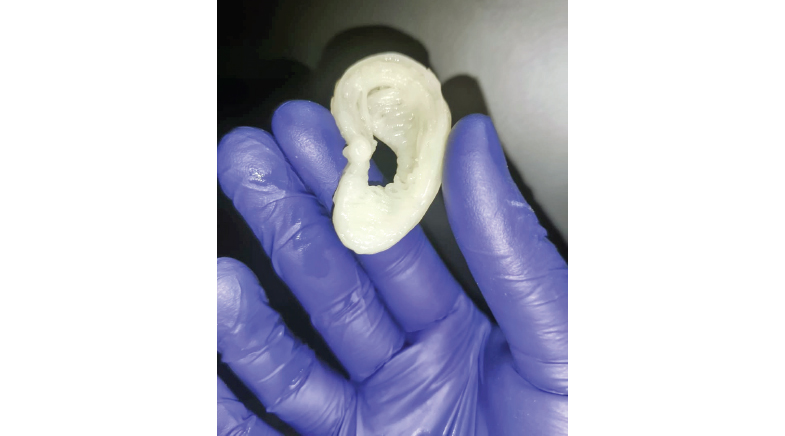

Seafields Solutions, a U.K.-based company where Elmer is the Head of Science, is exploring Sargassum as a marine carbon dioxide removal solution (The deep carbon sink). Seaweed can be dried and sunk to the bottom of the ocean to lock away the carbon — but this has yet to be realised. "Until we have the verification that it is safe, we are mainly focusing on making products from the Sargassum," says Elmer. These range from biofuels to bioplastics, biostimulants and biochar, for which Seafields is partnering with other companies.

"We have a partner company, RubisCO2, that works... in Mexico on making biochar from Sargassum," says Elmer. Biochar is a carbon-rich product made by the pyrolysis (thermal decomposition) of biomass with applications in agriculture and construction. "They have been selling their biochar to local construction companies that put it into concrete," she says.

By intercepting the seaweed before it lands on the beach for making products, Seafields is keeping methane – a potent greenhouse gas – out of the atmosphere. But the same seaweed can be converted into methane for producing electricity.

GOING WITH THE FLOW

Seven years ago, Benjamin Nestorovic, a Swedish science student, was in Mexico when he first encountered Sargassum. "That was a very bad year," Nestorovic recalls. The annoyance of not being able to swim due to the algal bloom turned into inspiration and led to the founding of his start-up SarGas years later. Having studied how to turn seaweed into energy, Nestorovic knew that the farming and harvesting of seaweed was a big challenge. "Here it's just on the beach."

Nestorovic and his second-degree connections in the island nation of Grenada saw promise in making biogas from seaweed. Biogas is made when bacteria munch on organic matter in an oxygen-free environment. Back then, there wasn't much research on how to turn Sargassum into useful products because these algal blooms started in 2011, Nestorovic says. "We managed to set up a pilot project there about four years ago." The pilot is located at a hotel, which has been using the biogas in its bakery.

SarGas, founded in 2023, is now building a large-scale biogas plant. Though biogas is a commercialised technology, seaweed was a new substrate, says Nestorovic, Chief Executive Officer of SarGas. Along the way, he carried out research in association with the KTH Royal Institute of Technology in Stockholm, where he graduated from, to maximise the methane output of biogas. Nestorovic and associates tried various mixes of seaweed with other organic wastes and pre-treatment methods, such as chopping the seaweed and enzyme treatment, to reach an output of 60% methane.

What's left of the seaweed that has decomposed, says Nestorovic, is called the digestate and can be used as fertiliser. "So, there's two products in one." But scientists have warned that seaweeds tend to accumulate heavy metals that may transfer to the fertiliser and crops (bit.ly/As-Cd). "We've also done tests on arsenic and cadmium," Nestorovic says, and found low levels in the fertiliser in Grenada. "It depends on how Sargassum has travelled on the ocean... and if it's in certain waters that lack nutrients, it will instead attract heavy metals to grow." Mixing Sargassum with other organic waste reduces both the salt and heavy metal content in the fertiliser, he adds.

In the Caribbean, what was – and still is – an environmental crisis has turned into an opportunity to provide cheaper electricity and fertiliser. But the question is whether businesses can sustain against the ebb and flow of Sargassum in nature. Nestorovic realised early on that he needed to develop a storage solution. With silage technology, he found, seaweed can be stored for a year before it starts to lose its energy content. The method involves packing seaweed in plastic bags and reducing its pH to prevent fungal growth. "It's basically pickled."

Elsewhere in the world, other innovative uses of seaweed are surfacing. In Germany, the start-up Vyld is making tampons from brown algae — and calling them 'Kelpons'. Australia-based FutureFeed is making methane-reducing feed for livestock from a red seaweed. "If we give 40 gm of... red Australian seaweed to each and every cow on the planet, the impact on the climate would be equivalent to [stopping] each and every car on the planet overnight," says Doumeizel. Studies have also shown that when used as an animal feed additive, seaweed reduces the use of antibiotics.

For seaweed-based products to scale and keep up with the fossil fuel industry, however, cultivation that brings down the cost of seaweed is the way forward. "If we start to tap into the wild seaweed stock, then the stock will disappear very quickly," warns Doumeizel, who founded the Global Seaweed Coalition to ensure a safe and sustainable seaweed industry.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH