Aiming high — with food, flights and factories

-

- from Shaastra :: vol 02 issue 06 :: Nov - Dec 2023

Start-ups grade veggies and fruit, ease aviation and train robots to perform a spectrum of tasks.

Agrograde (Occipital Technologies Pvt. Ltd.)

Founders: Kshitij Thakur and Rakeshkumar Barai

Year: 2018

Big idea: Using AI, computer vision and ML to grade and sort fruits and vegetables

Kshitij Thakur was still in college when he found a solution for people who wanted to buy footwear online but were worried about size and suitability. The company that the mechanical engineering student set up with a friend provided would-be shoppers with a virtual trial room using computer vision. This led to his present venture — Agrograde — which has built a grading and sorting machine for fruits and vegetables using computer vision and machine learning (ML).

Agrograde had earlier developed a mobile application that worked with images of fruits and vegetables, and digitised quality checks. The quality checks in the horticulture industry are almost entirely manual and subjective. There is hardly any grading of the produce in terms of quality, size and shape. Further, farmers who transport their produce to distant markets often do not earn enough to justify the transportation cost. These were the problems that Thakur hoped to deal with when he and co-founder Rakeshkumar Barai started Agrograde.

The mobile application, built in 2019-20, helped them to understand quality and other parameters in vegetables and fruits, Thakur says. They started with potatoes and onions. Agrograde collected quality manuals from major retailers and export houses. They reached out to farmers to understand quality issues at the production end. "We asked the farmers to send images of their produce and we used that to train our AI (artificial intelligence) models. That is how we collected images at every node of the supply chain," Thakur says.

The aim was to build a machine and use technology to automate these activities. With the database they had built, they trained their AI models on quality parameters — colour, shape of the produce and so on. They checked out different business models before they launched the machine commercially, starting with Maharashtra and Uttar Pradesh. The Pune-headquartered company now offers its services in several other States. It deals with aggregators, farmer-producer organisations and other players in the value chain. Its machines can also be used to grade lime, sweet lime, tomatoes, apples, guava and sapota.

Agrograde works in the clusters where production happens, and offers its machines either on outright purchase or lease or a pay-per-use model. The company has raised about ₹2 crore from investors.

BluJ Aerospace Pvt. Ltd.

Founder: Maruthi Amardeep Sri Vatsavaya and Utham Kumar Dharmapuri

Year: 2022

Big idea: Developing a VTOL aircraft for cargo and passengers using electric-hydrogen propulsion

In 2022, while starting up their company, two aeronautical engineers wanted to name it after the blue jay, which also happens to be the State bird of Telangana, but the name and its variants had already been taken. So, they came up with the shortened BluJ for their company, which is building a Vertical Take-Off and Landing (VTOL) aircraft that will fly on electric batteries and hydrogen fuel cells. The first aircraft will be used for freight movement. A few years down the line, the company plans to come out with one for ferrying passengers.

"The whole idea behind BluJ is to make aviation simple and sustainable," says one of the two founders, Maruthi Amardeep Sri Vatsavaya. "We felt VTOL was the perfect solution for that. We wanted to do with aircraft what cell phones did to telecommunications."

The company is working on its first aircraft, which will have a 100-kg payload and a 400-km range, according to co-founder Utham Kumar Dharmapuri. It will be able to achieve this because of its propulsion system, he adds. Most players with VTOL aircraft use purely electric batteries, whereas BluJ will employ electric batteries in combination with hydrogen. This will be more energy-efficient than batteries. While the electric batteries will power the aircraft during take-off and landing, hydrogen fuel will give the aircraft its range. The electric-hydrogen propulsion will help reduce its weight.

BluJ plans to demonstrate its first prototype in three months. It is building various parts and is testing some of the systems. VTOL aircraft, according to Utham Kumar, will need only about 10,000 square feet to take off and land. The two, who were classmates at the Institute of Aeronautical Engineering, Hyderabad, hope to launch the 6m x 4.5m aircraft for commercial freight operations in two years. The passenger aircraft, which BluJ plans to build after 2028, will be able to seat 10 people.

The Hyderabad-headquartered company will seek certification for the aircraft under The Drone Rules of the Government of India. Apart from a few grants, the company has raised seed funding from private investors. The entrepreneurs say that the production facility they now have is good enough for building prototypes and for certification purposes.

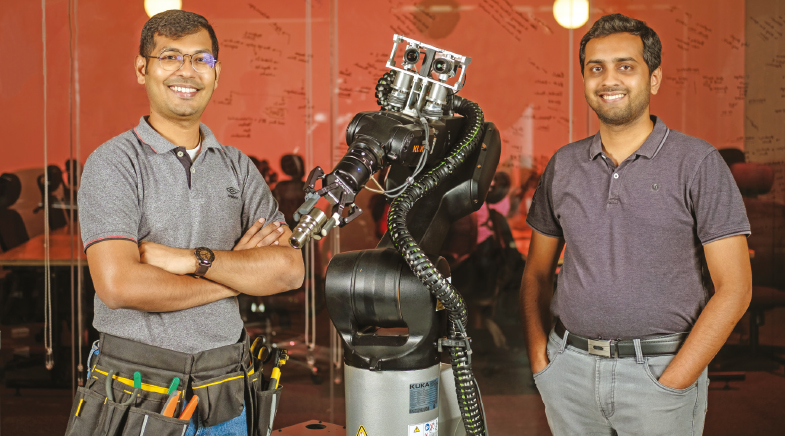

Cyn:Lr (Cybernetics Laboratory)

Founders: Nikhil Ramaswamy and Gokul N.A.

Year: 2019

Big idea: Helping build universal factories with a fleet of visual robots

Nikhil Ramaswamy and Gokul N.A. were colleagues at National Instruments, a global automated test and measurement systems company. It was there that the two electronics and instrumentation engineers honed their interest in machine vision and artificial intelligence, which led them to set up Cyn:Lr, short for Cybernetics Laboratory. The company is building a robot platform that will enable robotic arms in manufacturing companies to intelligently grasp objects and place them in the correct position. It is part of the machine vision domain, says Gokul. The idea is to help build universal factories comprising uniform visual robots that need no training or custom engineering to manipulate objects.

Just like humans can pick up unknown objects, Cyn:Lr's technology enables robotic arms to grasp any object without prior training. The robotic arm is equipped with a vision that is intuitive. Gokul explains that the company provides a brain and an eye for every robotic hand so that the robot is able to pick up a part and then place it where it has to be put.

"Ours is a universal machine vision-enabled robot platform that can sense the clutter and manipulate objects (the way) human beings can do," Gokul says. The capability for a robot to pick up a particular part from a clutter does not exist anywhere else now, he adds. A robotic arm may cost about $30,000; for a customer to translate that into a solution, it would cost between $150,000 and $250,000. It also would take 15-24 months to build that capability for one system. Without Cyn:Lr's technology, the robots would not be capable of adapting to any change in the environment — be it in the lighting or in the orientation of the product. The technology — the hardware and the machine vision — equips robots with this capability, giving them dynamic vision. This would standardise the automation infrastructure, system integration would be minimised and the same robot could be used for performing multiple and diverse operations — say, assembling a mobile phone or placing an airbag in a car.

According to Gokul, Cyn:Lr provides the complete platform, including the cameras and the software, and uses machine learning and artificial intelligence to train the robots to perform a variety of tasks. The company is executing paid pilots with two leading global automobile manufacturers. Their solution could be used in any industry with discrete manufacturing practices. To begin with, the company will target the automotive and logistics industries, particularly warehouses where different objects have to be picked and placed in designated slots.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH