Up and about

-

- from Shaastra :: vol 05 issue 01 :: Jan 2026

Saving time, costs and lives.

DASHAMLABS

Founders: Ankit Jhanwar, Apoorv Balwani and Devakar Dhingra

Year: 2024

Big idea: Innovative methods for developing silica aerogel sheets

The three entrepreneurs wanted to name their start-up after a globally accepted concept of Indian origin. So, Ankit Jhanwar, Apoorv Balwani and Devakar Dhingra zeroed in on the decimal point system, called dashamlav in Hindi. Playing on this word, they called their venture — a manufacturing company producing flexible silica aerogel sheets for insulation — DashamLabs.

The men have a background in science and engineering. Jhanwar, who has an integrated Master's in Polymer Science, had earlier worked with Dhingra and knew Balwani from their time at the Indian Institute of Technology Roorkee. Balwani and Dhingra are both from Clemson University, U.S.; Balwani holds a PhD in Chemical Engineering, and Dhingra a Master's in Mechanical Engineering.

Jhanwar says the silica aerogel sheets being built by DashamLabs are ideal for large-scale industrial and mobility applications. While silica aerogel is an established technology, the company's innovation is in the production process. According to him, the company uses a proprietary ethanol-based supercritical drying process that enables solvent recovery. This is one of two differentiated manufacturing routes the company has developed, he adds. In the first case, the supercritical CO2 is replaced with ethanol as the working solvent, allowing the company to achieve more uniform pore structures and produce consistently high-quality aerogel, he says. The company has engineered a closed-loop solvent recovery system that achieves near-complete ethanol recovery and reuse, effectively eliminating solvent costs. It reduces the overall production cost by 20-25%.

The second method removes the need for supercritical conditions. By operating at near-ambient pressure and substantially lower temperatures, the company significantly reduces both capital expenditure and operating costs. This process also provides for greater flexibility in tuning aerogel properties for different applications. He adds that once scaled, this route is projected to reduce costs by 45-50%, compared with traditional supercritical drying-based manufacturing.

Jhanwar says DashamLabs has achieved success in the laboratory and conducted scale-up experiments to produce aerogel sheets. The equipment is expected to be in place early 2026, and production is to start in April-May 2026. Its plant is coming up about 65 km from Gurugram.

The aerogel sheets can typically be used for insulation for temperatures from negative to up to 600ºC, but the company will target users in the 100-600ºC range. This will include industries that use boilers, and those in aerospace applications.

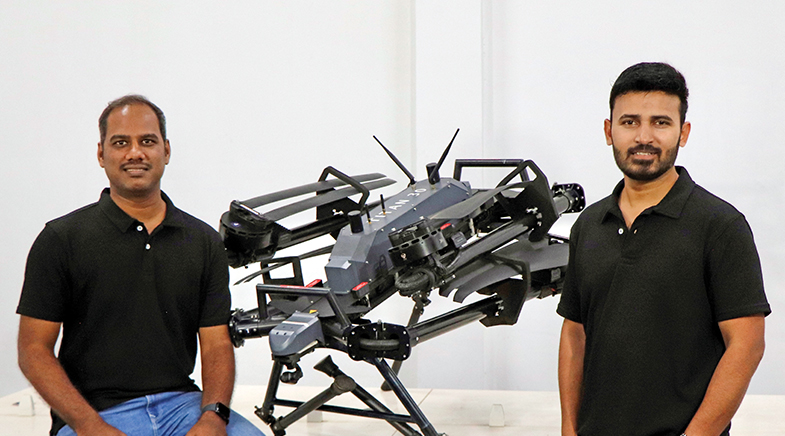

UNMANND AUTONOMY

Founders: Yeshwanth Reddy and Hemaditya Prasad

Year: 2025

Big idea: To build smart, autonomous drones

After working on drones in his first two start-ups, Yeshwanth Reddy decided to focus on drones for the defence sector. So, Reddy, who had completed his Master's in Aerospace Engineering from the Indian Institute of Technology Bombay, teamed up with Hemaditya Prasad, with whom he had founded his first start-up. Reddy and Prasad, who graduated in Electrical, Electronics and Communications Engineering from the Ballari Institute of Technology & Management in Karnataka, set up Unmannd Autonomy to develop smart drones that could navigate autonomously in GPS-denied environments, meeting defence needs.

"The next decade is not about who is going to build a drone that is large, or fast, or heavy. It will be all about autonomy. Whichever is the smartest drone will be the last drone standing or the one that will achieve its mission," says Reddy.

The start-up is building intelligent drones that can perceive their environment, understand the landscape as humans would, and make decisions autonomously by keeping the mission in focus, he explains. Such drones would be particularly useful in conflict zones where GPS navigation may not be possible due to electronic interference and jamming. Unmannd has equipped its drones with vision and acoustic sensors, and spectrum analysers, which help them navigate autonomously. The data from these sensors are fed into Unmannd's proprietary software stack to give the drone the best real-time understanding of the environment.

According to Reddy, Unmannd's first product — Titan 30 — is production-ready. It is meant for use in high-altitude locations, and could be of use to the Army, which uses mules to move its day-to-day cargo at the frontline in high-altitude regions. The Titan 30 will have a payload capacity of 30 kg and can fly to a height of 20,000 feet. The next drone in this series, Titan 60, will have double the payload capacity, he adds.

The second product, Fury, is an interceptor drone that can be operated with or without explosives. Without explosives, it can intercept drones that weigh less than 10 kg. It can carry 300 g of radial explosives and intercept drones of even up to 200 kg in weight in an 8-10-metre range, Reddy says.

ANSCER ROBOTICS

Founders: Ribin Mathew, Ebin Sunny, Raj Mohan, and Raghu Venkatesh

Year: 2020

Big idea: Building autonomous robots for material handling

Ribin Mathew's tryst with robots started when he was a student of Mechatronics at the Nehru College of Engineering and Research Centre at Pampady, Kerala. He and his classmate, Ebin Sunny, participated in several tech fests. The two wanted to start a company but decided to gain some work experience first. They worked at a Delhi-based robotics company, where they met Raj Mohan, who had a Master's in Robotics and Automation from Amrita Vishwa Vidyapeetham. The three, along with Raghu Venkatesh, whom they met at a makerspace community, went on to found ANSCER Robotics — ANSCER standing for Autonomous Navigation System for Controlled Environment Robots.

The COVID-19 pandemic forced a global shutdown, but helped the young start-up, which was located in an incubator that had all the facilities the team needed. Since they could not venture out, they worked through the lockdown to develop the product, finalise the design, and build the software.

PHOTO: BY SPECIAL ARRANGEMENT

ANSCER’s product

According to Mathew, the company manufactures robots that autonomously navigate and perform assigned functions in factories and warehouses. The company purchases the required components and builds the robots at its 30,000-square-foot facility in Bengaluru. The company also develops the required software. More than half of the 85-member team is involved in software development.

ANSCER Robotics makes robots that can lift payloads from 100 kilos to 2.5 tonnes, and lift them up to 3.6 metres. Some models can reach speeds of up to 3 metres/second. The robots are used to move raw materials to assembly lines in factories and to transport finished goods to warehouses. The company's first customer was the Indian subsidiary of a multinational that wanted to test whether the robots could be deployed at its manufacturing plant. Their first product was out for commercial trials in 2023.

Founders (from left) Ebin Sunny, Ribin Mathew, Raj Mohan, and Raghu Venkatesh.

Mathew says that the robots are equipped with powerful cameras and Light Detecting and Ranging sensors that help them navigate even in low-light conditions. The robots detect obstacles on the way, wait for them to move, or navigate around them to reach their destinations. Operating the robots is similar to booking a cab or sending parcels on an app — the pick-up point and the destination can be programmed, and a robot assigned to do the job, he says. "We use 3D-vision cameras. We load a lot of sensor information into the robots, and they can make decisions on the go," says Mathew.

Have a

story idea?

Tell us.

Do you have a recent research paper or an idea for a science/technology-themed article that you'd like to tell us about?

GET IN TOUCH